New addition to Monforts technological team

Monforts will highlight its advanced finishing and coating technologies for the production of technical textiles at the upcoming Techtextil North America.

11th April 2018

Innovation in Textiles

|

Mönchengladbach

Monforts, a leading textile machinery manufacturer, will highlight its advanced finishing and coating technologies for the production of technical textiles at the upcoming Techtextil North America, which takes place at the Georgia World Congress Center in Atlanta from 22-24 May.

Monforts, a leading textile machinery manufacturer, will highlight its advanced finishing and coating technologies for the production of technical textiles at the upcoming Techtextil North America, which takes place at the Georgia World Congress Center in Atlanta from 22-24 May.

“Techtextil North America is a very important show for us, because technical textiles are a key pillar of our production programme and North America is one of our major markets,” said Monforts Head of Technical Textiles, Jürgen Hanel.

“Technical textiles are extremely diverse in their end-use applications and our customers range from manufacturers of substrates for digitally-printed soft signage to those making high-performance composites. We have also provided dedicated lines for producers of airbags, flame retardant barrier fabrics, filter media, heavy duty membranes and even base liners for sensor-packed dye sensitive solar cells.” The needs of the manufacturers of all of these very different materials, he adds, are still uniform in many respects.

“They all require expert coating and finishing for maximum efficiency, and they need technology which provides the ultimate in flexibility and the ability to switch quickly from one fabric formula to the next, without compromising on the economical use of energy or raw materials. Many of our customers need to operate 24 hours a day over seamless shift systems.”

The European-built Montex range of stenters has earned its leading position on the market for fabric drying due to the robustness, reliability and economy of these machines. In specialised, integrated lines for nonwovens finishing, for example, they are equipped with a padder and slitter, a stretcher with a force of up to 10,000 N in longitudinal direction, and reinforced tracks with maximum transverse forces of 10,000 N. These nonwoven lines can accommodate materials in the extremely wide range of 100gsm up to 5,500 gsm for materials in thicknesses of between 0.5-22mm.

The Montex range for the fixing of 3D warp knitted spacer fabrics for products, such as car seats and mattresses, meanwhile incorporates a cooling chamber for efficient cooling of the bulky materials.

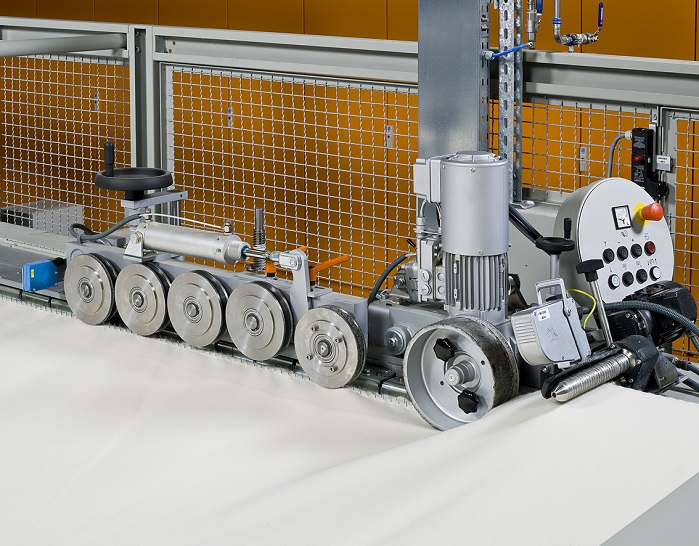

For the coating of technical textiles, Monforts offers two highly versatile systems – the texCoat module, which can be integrated into new lines or retrofitted into existing ones, and the Montex Allround designed to be integrated into a complete Monforts finishing range.

“The acquisition of Austria-based Timatec and the integration of its range into the Monforts portfolio has further strengthened the company’s position in respect of coating technology,” said Mr Hanel. “Nowadays we are the only manufacturer which can offer completely integrated coating lines from a single source, and the coating machine is tailored to the subsequent Monforts drying technology – with all the benefits resulting from fully integrated plc control.”

“Our system has the shortest fabric path from the coating unit into the stenter and we have all variations of coating application systems too – and all of these options are available in wider widths, with the engineering and manufacturing from a single source here in Europe.”

The instant connectivity and easy distribution of know-how is certainly changing the face of industrial manufacturing. “Digitisation is making the operation of complex machinery much simpler and cutting down the required training periods, while at the same time, reducing the chance of human error and this is certainly the case with our latest Qualitex 800 control system,” said Mr Hanel.

The system is available for the automatic and continuous operation of the company’s Montex stenters, Thermex and E-Control continuous dyeing ranges, Monfortex and Toptex shrinking systems and Eco Applicator, texCoat and Allround coating units.

Business intelligence for the fibre, textiles and apparel industries: technologies, innovations, markets, investments, trade policy, sourcing, strategy...

Find out more