Further funding for Spinnova

Opinion

€30 million pilot production plant to be built in Lappeenranta in south-east Finland.

27th January 2022

Adrian Wilson

|

Espoo, Finland

Nordic Bioproducts, a spin-off from Aalto University, is the owner of patented AaltoCell technology and has quickly succeeded in developing a new plant-based textile fibre called Norratex which is manufactured without any toxic chemicals or expensive solvents.

Norratex fibre can be made from forest industry by-products, textile waste and ordinary paper pulp – a significant advantage over traditional viscose, which is made from dissolving pulp which can cost up to 30% more. The fibre’s properies were described as “close to viscose, with cotton-like properties”, but with the longer term potential to become a replacement for polyester.

The new fibre making process is being viewed as a drop-in solution for existing viscose fibre plants, to eliminate the use of toxic carbon disulphide, and could also offer a route to the recycling of mixed material textiles because on a laboratory scale, natural fibres have already been neatly separated from plastics into clean fractions.

A €30 million pilot production plant will now be built in Lappeenranta in south-east Finland close to six existing pulp manufacturing plants, with an annual capacity of approximately 10,000 tons of Norratex.

Competition in the field of new textile fibres is accelerating and the first players in the industry are already commercialising their products and approaching industrial-scale production. Many of these innovations are Finnish, such as Aalto University’s existing Ioncell fibre, Metsä Spring’s Kuura fibre, Spinnova’s fibre and Infinited’s Infinna.

“We are very excited about this new collaboration,” said Bernardita Araya, manager of CMPC Ventures. “For CMPC, it represents a significant step towards establishing a leading role in the development of the future of biobased industries with global impact. This technology is easy to scale for producing fibres in a suitable price range and there has been a lot of interest from the market. We are in a good position to take this product quickly to commercialisation.”

Background

In 2020, Nordic Bioproducts began to develop a cost-effective and scalable textile fibre manufacturing process in collaboration with the University of Tampere, based on the ideas of Professor Olli Dahl at Aalto University.

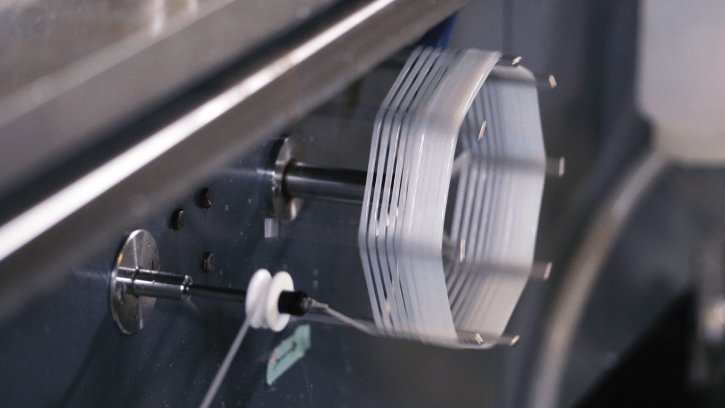

The Aaltocell process has been explored for textile fibre production for several years. Using the patented method, cellulose is first processed into small-particle cellulose, after which it is further processed into a viscose-like textile fibre.

The first wet spinning experiments using the Nordic Bioproducts cellulose dissolution method were performed in June 2021. Only six months later, in November, yarn was already being from Norratex textile fibre at the University of Tampere. Several samples of the yarn were then knitted at the Department of Design at Aalto University.

Surprise

“The seventh spinning experiment really surprised me,” said Maija Järventausta, a researcher who carried out the wet spinning and yarn production at Tampere. “The dope was excellent and it did not clog the spinneret during wet spinning. At that moment, I suggested that we should try making yarn for the first time. In the next step, the carding was successful, the fibre withstood opening, curled beautifully and no pilling was formed. Fibre-to-fibre friction was optimal. I would never have believed that in such a short period of product development, we could succeed in a functional end product. It was great to see that the yarn was strong enough not to break in the knitting process. The yarn also has a beautiful subtle gloss – a feature that lasted from wet spinning to the dry yarn.”

“Succeeding so soon came as a big surprise to our entire team,” said Nordic Bioproducts R&D director Ville Nyman.

Professor Dahl was convinced from an early stage that the method could be applied in the production of plant-based textile fibres.

“It’s great to see your own ideas lead to new products from a skillful team of engineers in a young company,” he said. “We are embarking on a new era in developing novel biobased products.”

Business intelligence for the fibre, textiles and apparel industries: technologies, innovations, markets, investments, trade policy, sourcing, strategy...

Find out more