Sciessent launches Pilltec anti-pilling technology

Introduction follows three years of research, engineering design, testing and critical evaluation at James Heal.

6th May 2025

Innovation in Textiles

|

Halifax, United Kingdom

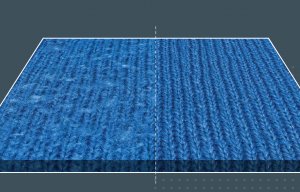

James Heal’s latest Martindale Motion enables users to achieve higher productivity and efficiency cost savings in abrasion and pilling testing.

The redesigned nine-station Martindale instrument with individual lifting heads offers the flexibility to run each station independently for running different textile tests simultaneously.

Historically, having worked with Dr Martindale of WIRA in the 1940s, James Heal created the first Martindale test instrument. When it hit 80 years of existence, the company’s development team decided it was time to take a fresh look at this classic instrument.

Multiple textiles can now be tested at the same time through to conclusion without intervention. Once set up, the Martindale Motion can be left running with the sample holders automatically lifting at the required evaluation points, freeing up the operator’s time to do other work without the need to return until the abrasion or pilling test is fully completed, including overnight.

Each sample is kept in-tact at the end point for evaluation and checking, reducing queries on grading and the potential need for re-testing. Further refinements include a new hinged access to change the self-aligning drive pins, allowing quick and safe switching between tests.

Designed and manufactured in the UK, the James Heal Martindale range has seen numerous updates, new models and innovations over the years such as touchscreen and user-friendly software, best-in-class safety features combined with the signature near silent running of this staple lab instrument. Added to this have been the introduction of the DurAbrasion multi-function testing machine, later followed by the market-leading evolution, the AquAbrasion wet abrasion tester launched in 2019.

Established in 1872, James Heal is an international engineering brand renowned worldwide for delivering premium quality and reliable materials testing solutions. From its core manufacturing and commercial headquarters in the United Kingdom, James Heal specialises in the design and production of textile testing instruments and test materials (consumables), supported by industry-leading service and support.

James Heal designs its testing instruments with the user in mind, offering the most user-intuitive and innovative solutions in textile testing. The brand also works closely with some of the biggest names in the automotive, paper, wood, plastics and glass industries to develop first-rate materials testing solutions.

Business intelligence for the fibre, textiles and apparel industries: technologies, innovations, markets, investments, trade policy, sourcing, strategy...

Find out more