Update for VABS simulation software

Warp knitting machine builder Karl Mayer has worked closely with its system partner Texion Software Solutions to develop Texion’s Procad warpknit 3D the latest addition to the Procad family of software solutions for manufacturers of warp knitted fabrics. Â The production of modern warp knitted fabrics is an engineering science in itself. Anyone involved should have specialist knowledge of yarn properties and finishing processes a

29th October 2008

Innovation in Textiles

|

Obertshausen & Aachen, Germany

Warp knitting machine builder Karl Mayer has worked closely with its system partner Texion Software Solutions to develop Texion’s Procad warpknit 3D the latest addition to the Procad family of software solutions for manufacturers of warp knitted fabrics.

The production of modern warp knitted fabrics is an engineering science in itself. Anyone involved should have specialist knowledge of yarn properties and finishing processes and, above all, should also have a clear picture of the lapping movements required in the creation of the fabric. The challenge goes out to experienced textile technologists, since the lapping movements needed to create a product are usually extremely complex and are affected by the dynamic conditions within the warp-knitted fabric which, in turn, are influenced by the yarn tension and yarn characteristics.

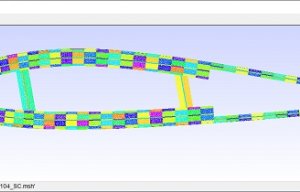

According to Karl Mayer, ProCad warpknit 3D system can help to stimulate the imagination of textile engineers. The latest piece of software in the proven ProCad family, enables drafted constructions to be displayed three-dimensionally and evaluated for the first time, right from the initial development stage.

ProCad warpknit 3D system enables drafts to be rotated as three-dimensional images, and enlarged so that even the smallest detail can be visualised. Sophisticated algorithms enable the tension effects to be reproduced realistically in the model. The various lapping arrangements can also be simulated and used to calculate and simulate textiles produced on single and double needlebar warp knitting machines with varying stitch densities, yarn feeds, yarn counts, colours and stretch levels.

ProCad warpknit 3D system enables drafts to be rotated as three-dimensional images, and enlarged so that even the smallest detail can be visualised. Sophisticated algorithms enable the tension effects to be reproduced realistically in the model. The various lapping arrangements can also be simulated and used to calculate and simulate textiles produced on single and double needlebar warp knitting machines with varying stitch densities, yarn feeds, yarn counts, colours and stretch levels.

ProdCad warpknit 3D obtains the data for calculating the three-dimensional fabric construction from the ProCad warpknit’s product database. As well as the yarn characteristics obtained from the ‘yarn atlas’, the fabric take-down and yarn feed sequences are also included in the calculation model, so that a physically correct picture can be obtained on the basis of the yarn parameters. Under normal circumstances, these are extremely complex technical procedures, which can be carried out easily and intuitively using ProdCad warpknit 3D.

The design can be ‘handled’ by clicking on the mouse and can be manipulated so that it rotates in all directions and enlarged or reduced in size by scrolling with the mouse. Other modifications that can be made to the lapping arrangement being drafted relate to changing the number of repeats displayed, the yarn count and the colour scheme, and the inclusion and exclusion of yarns according to the bars, and this is all done in real time. The results of this interactive processing technique can be evaluated immediately.

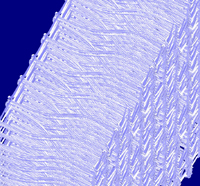

According to Karl Mayer, lapping movement technology is difficult to teach, especially to newcomers to the technology. The companysays that ProdCad warpknit 3D can simplify and accelerate the process of learning and understanding considerably, since the software enables the learner to get a grasp of the subject immediately. The lapping technology can be visualised both generally and in detail, and ranges from pillar stitch and tricot lappings to open and dense knitted fabrics. Changes in the lapping can be seen immediately and enable the interplay between several bars and the effects of different yarn tensions to be experienced.

Without software support, visualising lappings mentally requires a great deal of experience and concentration. ProdCad warpknit 3D enables the user to focus on the important details and concentrate on developing creative designs. The detailed simulation makes expensive and time-consuming trials on the machine no longer necessary and no production is lost as a result.

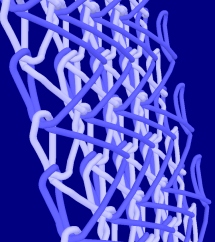

With its specific, cause related display features, ProdCad warpknit 3D supports the experience and expertise of the developer in discovering why and how certain effects are created. The initial fabric construction clearly shows the yarn passage through the machine. The user can then use this to simulate and reproduce the movement of the yarns and deformation of the fabric as a result of the yarn tension and yarn characteristics in a carefully controlled, step-by-step manner.

For the first time, the high degree of accuracy that can be achieved when simulating the yarn dynamics enables tricot fabrics to be represented as a fabric image which is very similar to the real fabric . This enables the product to be evaluated, without having to use precious machine time.

For the first time, the high degree of accuracy that can be achieved when simulating the yarn dynamics enables tricot fabrics to be represented as a fabric image which is very similar to the real fabric . This enables the product to be evaluated, without having to use precious machine time.

Specifications for functional textiles

Karl Mayer says that the technical textiles sector offers a huge growth potential and tapping into this potential requires products having special functional characteristics and that until now, developing lappings with the required specific characteristics has nearly always meant carrying out expensive, time-consuming trials. The company claims that ProCad warpknit 3D is the perfect answer to this, and is proving to be an indispensable tool for use in the creative design process.

Karl Mayer says that the technical textiles sector offers a huge growth potential and tapping into this potential requires products having special functional characteristics and that until now, developing lappings with the required specific characteristics has nearly always meant carrying out expensive, time-consuming trials. The company claims that ProCad warpknit 3D is the perfect answer to this, and is proving to be an indispensable tool for use in the creative design process.

The three-dimensional construction shown on the right provides good approximate values in conjunction with the relevant yarn parameters for important product characteristics, such as strength or flexural rigidity. Work is continuously being carried out into improving the calculation functions and on developing customer specific solutions to ensure that the model comes as close as possible to reality and that its design and structural features meet the requirements of the end-use. The structural data obtained can also be made available for use in external applications and calculations via a standard export interface.

Karl Mayer says that with all these features, ProCad warpknit 3D completes the ProCad product family and makes this extensive software package an efficient tool for turning the creativity of the designers in the design studio into reality. The individual programs were developed for the various stages in pattern preparation, and support development and data management throughout all the processes.

For further information visit www.texion.eu

Business intelligence for the fibre, textiles and apparel industries: technologies, innovations, markets, investments, trade policy, sourcing, strategy...

Find out more