Producing potable water with natural sunlight

New recycled leather is both biodegradable and recyclable.

9th October 2023

Innovation in Textiles

|

Hong Kong

In a project supported by the H&M Foundation, The Hong Kong Research Institute of Textiles and Apparel (HKRITA) has developed a new approach to recycling leather.

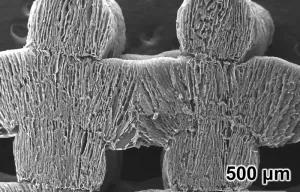

Traditional recycled leather is produced by combining shredded scraps and residual fibres of real leather with synthetic, non-biodegradable binders like PU and PVC. Much of the recycled leather also contains harmful chemical residues, such as chromium VI, which result from the tanning process.

In the reProLeather project, HKRITA has developed a process for separating the chromium VI from the shredded leather fibres and created a bio-based, alternative to the PU and PVC binders, creating a new form of recycled leather that is both biodegradable and recyclable.

The organisation is now seeking industry partners to optimise production properties and enhance functions, paving the way for improved industry applicability in the future.

“As a philanthropic change agent for the entire industry, we take risks to unlock needed solutions with the ambition to find technologies that can contribute to a planet positive fashion future,” said Christiane Dolva, strategy lead at H&M Foundation. “We’re happy to share our findings openly with others to find industry actors ready to adopt bold innovations and reProLeather could be one of these solutions. I hope to see it scale soon.”

Business intelligence for the fibre, textiles and apparel industries: technologies, innovations, markets, investments, trade policy, sourcing, strategy...

Find out more