PolyMed composite medical tubing at Compamed 2019

The company is presenting nonwovens with hydro-gelling fibres for advanced wound care, high-performance backing materials and transdermal applications.

18th November 2015

Innovation in Textiles

|

Weinheim

Freudenberg Performance Materials presents its medical product portfolio at the Compamed trade fair that is taking place in Dusseldorf this week.

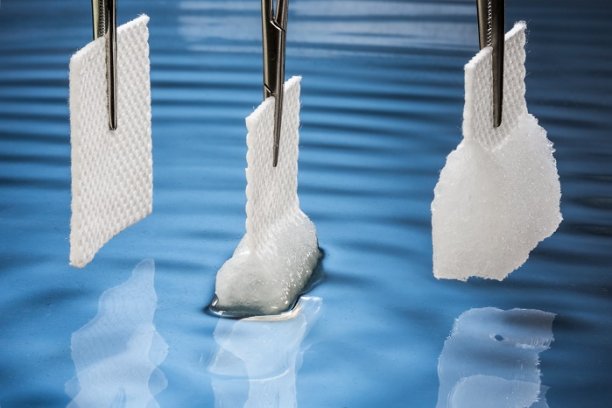

In addition to new solutions made from antimicrobial PU foam and chitosan nonwovens, the leading manufacturer of technical textiles is showcasing nonwovens with hydro-gelling fibres for advanced wound care, high-performance backing materials for wound care and transdermal applications, as well as activated carbon filters for ostomy applications.

The foam systems absorb wound exudate and create an ideal environment for wound healing. They protect the wound from drying out and ensure the free exchange of gases and water vapour, accelerating the wound-healing process.

“In recent months, working closely with our customers, we have greatly intensified the research and development of foam-based solutions. Our first successes include customized, antimicrobial polyurethane foam systems for medium to strong extruded wounds such as decubitus and second degree burns”, explained Marcus Simon, Manager Market Segment Medical at Freudenberg Performance Materials.

The antimicrobial effect contributes to reducing the bacterial load in infected wounds. It is also said to act as a barrier in wounds with high and renewed risk of infection. In the future, the company will also offer standardized solutions for a wide range of applications.

Another Freudenberg Performance Materials innovation is a standardized solution made from 100% chitosan fibres for use as a bacteriostatic wound pad material. Derived from the shells of shellfish, the chitosan biopolymer promotes healing and rapidly stops bleeding. This is said to enable a significant reduction in treatment time and costs, especially in the treatment of chronic wounds, the company reports.

Scaffolene technology is a further Freudenberg innovation, which is designed to enable the production of nonwoven fabrics from bioresorbable polymers. Scaffolene nonwovens are said to be extremely versatile in their characteristics and applications. They are flexible and tear-resistant in its dry state and stable even when wet, retaining its structure and avoiding clumping, according to the manufacturer.

Another advantage of the product is that during manufacture, antiseptic agents, enzymes or growth hormones can be incorporated directly into the nonwoven fabric. Depending on the raw material and additive used, scaffolene is said to enable active agents to be positioned and delivered precisely where they are needed in the body, promoting healing in chronic and acute wounds or helping to rebuild bones after a fracture.

Working together with customers, Freudenberg has initiated numerous product developments. One of these innovative product solutions is the combination of regenerative scaffolene wound matrix and antiseptic active ingredient. This project has been presented at Compamed to an audience of medical professionals by Freudenberg development partner Professor Birkenmeier of the University of Leipzig.

High-performance activated carbon filters from Freudenberg Performance Materials are used as integrated activated carbon filters in ostomy bags, targeted at the adsorption of unpleasant odours. Freudenberg Performance Materials adapts them to the individual requirements and specifications of its customers.

Thanks to the company’s ultra-modern production and finishing options, Freudenberg Performance Materials can offer a wide variety of ostomy filter variants, both on rolls and as a finished product.

Business intelligence for the fibre, textiles and apparel industries: technologies, innovations, markets, investments, trade policy, sourcing, strategy...

Find out more