Registration open for INDEX17

At the GKD stand, the focus will be on newly developed woven belts for the forming, bonding and drying of nonwovens.

17th February 2017

Innovation in Textiles

|

Heslington

GKD – GEBR. KUFFERATH AG, a leading technical weaver, will once again be presenting its solutions for the manufacture of nonwovens at the INDEX17 exhibition that will take place from 4-7 April in Geneva, Switzerland.

At the GKD stand, the focus will be on newly developed woven belts for the forming, bonding and drying of nonwovens. In addition, GKD will be premiering spiral belts from its own in-house production. The stand will also feature filter media made of woven metal mesh for polymer filtration and quench screens.

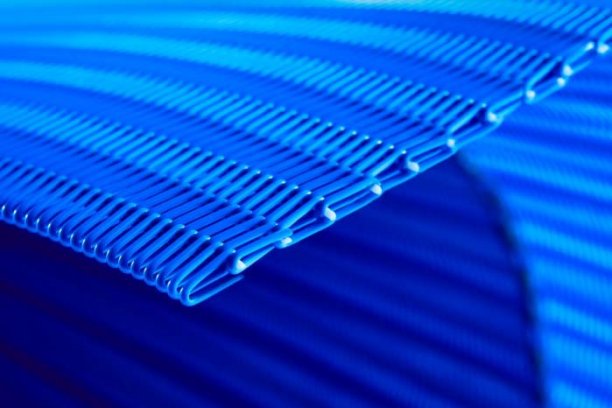

The highlight at the GKD expo stand in Geneva will be the newly developed laydown belt CONDUCTIVE 7690 for spunlaid nonwovens production. With no need for initial roughening of the surface of a new belt, full production speed can be reached again very quickly after a belt change, the company reports.

The rough belt structure in the running direction is said to ensure a high traction effect in the laydown zone and homogenous carded web formation. Yet in spite of its good grip, the new belt construction also ensures optimal web doffing.

In the meantime, the custom-coated belts first presented at the INDEX14 have gone through substantial further development and in Geneva this year GKD will be premiering the result: glass-hybrid woven belts with coating. A glass strand in the warp direction makes these belts lightweight but at the same time with plenty of cross-stability. For deployment in single and double belt dryers, they can be configured to be magnetic or non-magnetic depending on the specific application.

In starting production of spiral belts, GKD has made a significant addition to its portfolio as a belt specialist. From a single source, the company now manufactures spirals and belts. In doing this, GKD is responding to the queries of customers who want these types of belts but would prefer not to forego the all-round know-how – and the peace of mind - that this proven specialist for conveyor and process belts offers.

In response to the prevailing high machine speeds in nonwoven hygiene product manufacture, GKD offers highly flexible, self-tracking V-crimp type belts made of metal with special plastic cables woven in parallel to the running direction.

Their special construction is said to ensure trouble-free production – without additional belt tracking – at high speeds and with tight bending radii and high forces. Another GKD product that has proven itself in the production of nonwoven hygiene products is the electrostatically conductive belt made of CONDUCTO mesh with woven-in bronze wires.

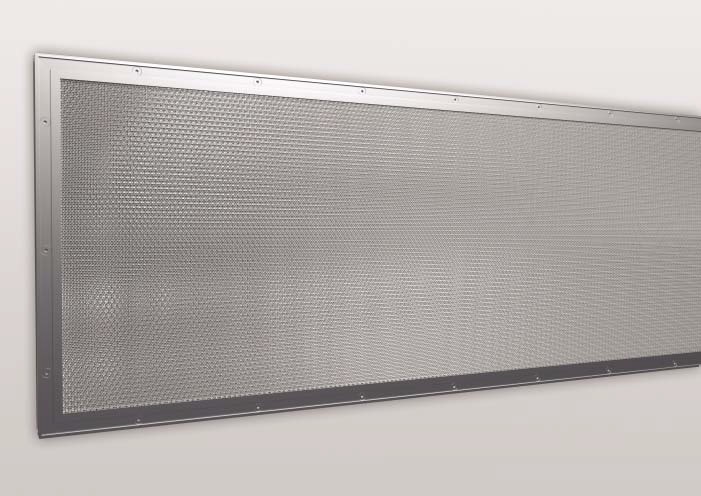

With filter media for central filters and spin beams, as well as quench screens, GKD proves its all-round competence in terms of the special needs of high-quality spunlaid production processes.

Multi-layer constructions of optimised dutch weave mesh (ODW) for process-specifically assembled filter discs or cartridges perform convincingly in screen changers. Made-to-measure, perfectly phased meshes in the spin beam optimise the service life of the spinnerets by ensuring reliable filtration of the flow of the melt.

Business intelligence for the fibre, textiles and apparel industries: technologies, innovations, markets, investments, trade policy, sourcing, strategy...

Find out more