Oerlikon Nonwoven closes a deal at IDEA

This investment marks the second nonwoven plant that Oerlikon has been able to place with leading European meltblown nonwoven manufacturers.

31st May 2016

Innovation in Textiles

|

Neumünster

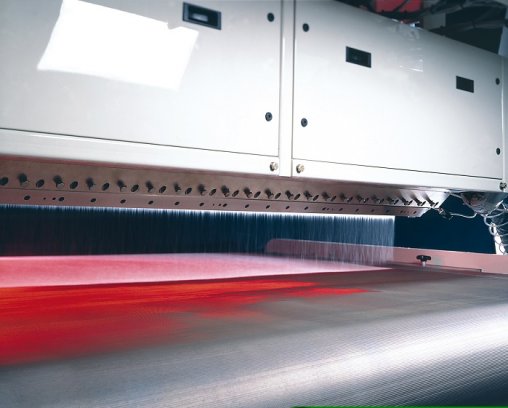

Following the recent investment by Scottish company Don & Low, another leading western European nonwoven manufacturer has invested in an Oerlikon Neumag meltblown plant.

The now signed contract comprises a system for the production of nonwovens made from polyolefins and other raw materials. The commercial production launch has been scheduled for the first half of 2017.

This investment marks the second nonwoven plant that Oerlikon Neumag has been able to place with leading European meltblown nonwoven manufacturers in a period of just a few months.

“The successes of the last few years demonstrate that we have not only secured our pioneering role with the constant further development of our market-leading meltblown technology, we have actually managed to expand it”, explained Axel Becker, Sales Director Nonwoven at Oerlikon Neumag.

“With our technology, our customers develop trailblazing products, hence strengthening their position within the global market and developing the products of the future with this technology.”

The market for meltblown nonwovens is expanding by an average of 6% per annum. The Oerlikon Neumag meltblown technology aims to enable the cost-efficient manufacture of high-end meltblown and SMS (spunbond-meltblown-spunbond) products.

Stand-alone monocomponent and bicomponent meltblown plants produce nonwovens for a whole range of filtration, insulation and sorption applications. As ‘plug & produce’ installations in already existing and new third-party composite systems, the meltblown technology is deployed for a whole range of medical and hygiene products.

This solution permits the cost-efficient upgrading of new or existing spunbond systems and offers nonwoven manufacturers access to markets with especially high quality requirements, according to the manufacturer. In addition to standard polymers, such as polyester and polypropylene, for example, promising polymers such as fluoropolymers can also be optimally processed.

Oerlikon is a leading technology group supplying growth markets with market-leading technologies and services for surface solutions, systems for manufacturing manmade fibres, transmission systems and drive solutions, as well as prevacuum and high vacuum technologies and pumps and the corresponding accessories.

With its Oerlikon Barmag and Oerlikon Neumag brands, Oerlikon Manmade Fibers segment is the market leader for manmade fibre filament spinning systems, texturing machines, BCF systems, staple fibre systems and artificial turf systems and – as a service provider – offers engineering solutions for the entire textile value added chain.

With the expansion of the product range to include polycondensation systems and their key components, the company now caters to the entire process – from the monomer all the way through to the textured yarn. The primary Oerlikon Barmag markets are in Asia, and – for Oerlikon Neumag – in the USA, Turkey and China.

Business intelligence for the fibre, textiles and apparel industries: technologies, innovations, markets, investments, trade policy, sourcing, strategy...

Find out more