Freudenberg at IDEA 2025

Applications range from construction and filtration to packaging and coating.

28th April 2025

Innovation in Textiles

|

Germany

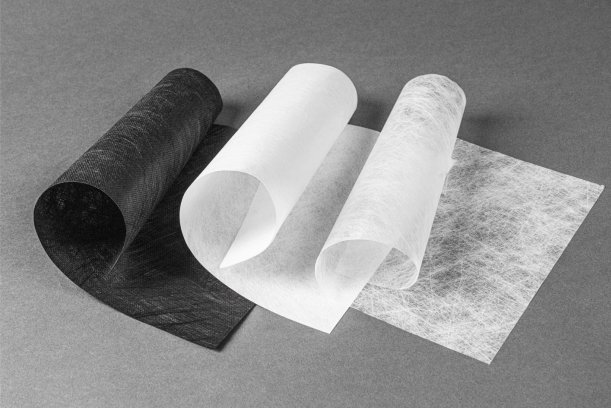

The unique fine filament nonwoven technology of Freudenberg Performance Materials enables materials to be engineered from a variety of polymers and blends using mono or bico fibres.

High flexibility and broad customisation options can provide benefits in a wide range of markets and applications – from roofing membranes to liquid filtration, as well as specific applications such as dehumidification products and artificial turf.

Fine denier spunbonds can be made of PET, PE or PP, not only in 100% composition but also in many different combinations, such as PET/PE, PET/coPET or PET/mPP, using mono or bico fibres in sizes ranging from 2.5 to 3 dtex. The material weights span 17 to 140gsm and they are strongly thermally bonded either by flat calendering or point sealing. The technology enables lightweight solutions with high tensile and tear strength to be created, as well as a smooth and uniform surfaces.

Ideally suited for construction applications such as roofing and facade membranes, vapor barriers and house wrappings, Freudenberg lightweight fine denier nonwovens complement the well-known Terbond, Texbond and Colback solutions for the construction market. They deliver mechanical strength and in particular a high nail tear strength as required by the market. Moreover, they have high UV and temperature resistance and stability thanks to the PET composition.

The fine denier technology is also marketed under the Filtura brand specifically for liquid filtration applications such as coolants and lubricants. The technology provides high efficiency and a regular surface, as well as new capabilities with PET-PA and PET-PE nonwovens. Support media applications for glass fibre, nano and activated carbon also benefit from these materials as protective layers.

The fully synthetic PET/PE fine denier materials are further ideal for packaging applications such as desiccant bags and other dehumidifier products. They enable the efficient and fast production of such pouches due to their exceptional hot sealing capabilities, with no need for chemical binders or additional treatments. Freudenberg’s technology provides high strength, high abrasion resistance and high durability, allowing for long-lasting desiccant bags.

In the coating industry, too, Freudenberg’s fine denier spunbonds contribute to enhanced process efficiency. The materials are chemically resistant and have good thermal stability. High-quality coating results can be achieved by using these materials as coating substrates, due to their smooth and even surface. The material properties can be customised for coating, laminating and concealing applications with different combinations of polymers, fibre types and bonding technologies. A specific very lightweight flat bonded variant of the material, for example, is an ideal coating substrate for cold wax depilatory strips, providing the necessary high mechanical strength and material flexibility.

Business intelligence for the fibre, textiles and apparel industries: technologies, innovations, markets, investments, trade policy, sourcing, strategy...

Find out more