Promoting good sleep with Outlast

Heat and moisture regulating PCM viscose fibres are said to offer a natural solution for climate comfort in bedding and apparel products.

14th November 2014

Innovation in Textiles

|

Heidenheim

Outlast Technologies, a market leader for temperature regulating phase change materials (PCMs), has enlarged its product range and is launching its new Universe performance filling material.

Heat and moisture regulating PCM viscose fibres are said to combine perfectly with cosy downs and offer a natural solution for climate comfort in bedding and apparel products, the company reports.

The heat managing Outlast PCM viscose fibres, 10 mm short cut fibres with 7 dtex, form one part of the new filling material Universe (30% viscose Outlast, 70% down).

Such a thick fibre with a high diameter was deliberately selected. “So we can guarantee a high loading of phase change materials (PCMs),” explained Martin Bentz, Managing Director of Outlast Europe. “The performance compared to a standard PCM viscose fibre here is four times higher.”

In combination with the down, Outlast has developed a product offering optimum thermal comfort. The downs display their advantages like lightness, fluffy volume and naturalness, the Outlast PCM viscose fibres regulate and optimise the climate comfort. Overheating and sweating are said to be reduced significantly.

“In conjunction with our well-known partner Kelheim Fibres, we are happy to have successfully obtained this new process – a homogeneous blend where both wash and care requirements are ensured,” said Martin Bentz.

Thus, Outlast has further tested on filling material and found out that PCM filling materials are ideally suited to provide an optimum heat and moisture management.

“The air transports body heat quickly to the performance fibres,” explained Volker Schuster, Director R&D at Outlast Europe. “One important aspect is that all fibres inside a filling altogether build a huge surface. And all fibres are flowed around by air. Therefore every fibre can react very quickly to temperature changes. Since the airflow is increased, this allows the PCMs to be more active in loading and discharging”.

The new PCM filling material optimises the climate proactively – contrary to other technologies that are merely transporting sweat, according to Outlast.

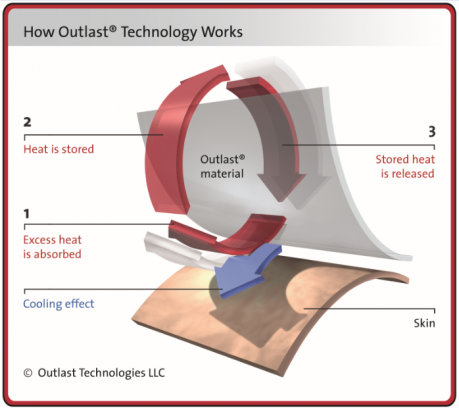

Outlast technology has been designed to proactively manage your skin temperature while controlling the production of moisture before it begins.

By using the new down/PCM viscose fibre blend the material costs of an end product (in comparison to the use of 100% down) can be reduced while also offering an interesting added value and more performance, the company adds.

Outlast technology was originally developed for NASA to protect astronauts from temperature fluctuations in space.

It utilises phase change materials (PCM) that absorb, store and release heat for optimal thermal comfort. This gives any product containing Outlast technology the ability to continually regulate skin’s microclimate. As the skin gets hot, the heat is absorbed, and as it cools, that heat is released.

Business intelligence for the fibre, textiles and apparel industries: technologies, innovations, markets, investments, trade policy, sourcing, strategy...

Find out more