Isbjörn of Sweden strengthens partnership with PrimaLoft

PrimaLoft develops its first insulation made entirely from recycled PET bottles with no compromise on performance.

8th May 2018

Innovation in Textiles

|

Latham, NY/Munich

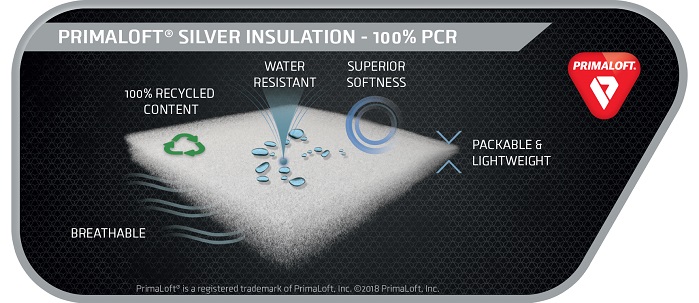

PrimaLoft, a materials science company specialising in technical products, is introducing it first high performing insulation made entirely from recycled PET bottles. The company will present the results of intensive research, introducing new PrimaLoft Silver Insulation – 100% PCR and PrimaLoft Black Insulation – 100% PCR, as well as PrimaLoft Gold Insulation Luxe at next month’s OutDoor Show in Friedrichshafen.

According to the company, the challenge in producing a high-performance insulation made entirely from post-consumer recycled (PCR) material had been that the melting points of the collected PET bottles used to create the recycled fibres differ from that of virgin fibres, which made the production of a stable insulation fibre that meets performance standards very difficult.

In response, PrimaLoft developed special recycling and production processes, resulting in the production of “extremely high-performance fibres” that are “finer and softer than cashmere and boast high bulk density and unmatched thermal performance”, according to the manufacturer.

The insulation is said to offer all the renowned properties that have made PrimaLoft the benchmark in performance insulation, such as low weight, high compressibility and water-repellent characteristics. Around nine commercially available PET bottles are necessary to create the insulation layer for one jacket (thickness 40g / m2).

“With the new 100%-PCR insulation, we offer our customers the perfect product that combines performance, comfort and sustainability. The response from our brand partners has been overwhelming so far. This innovation is also another important step towards achieving our own sustainability goals,” said Jochen Lagemann, Managing Director PrimaLoft Europe and Asia.

By 2020, PrimaLoft plans to produce 90% of its insulation products with at least 50% recycled fibre. Most recently, the ingredient brand had provided its pinnacle products, PrimaLoft Gold Insulation and PrimaLoft Gold Insulation Active +, with 55% recycled content.

An outdoor specialist Vaude became one of the first companies to use the sustainable synthetic insulation for its products. Starting in the winter season 2018/19, Vaude will convert all products that were previously equipped with PrimaLoft Silver and Black Insulation to the 100% PCR versions by summer season 2019.

“One of our key goals is to reduce the use of fossil fuels in our products and create closed circuits. PrimaLoft provides us with innovative solutions on this path ‘away from the oil'. Thanks to our longstanding ingredient partner, we are delighted to be able to use high-performance insulation made from 100% recycled material for the first time,” commented Aaron Bittner, Head of Apparel at Vaude.

Other partners of the first hour in sports and fashion include: 66 North, Armed Angels, J Lindeberg, Maloja or Sweet Protection.

Business intelligence for the fibre, textiles and apparel industries: technologies, innovations, markets, investments, trade policy, sourcing, strategy...

Find out more