Touch-activated freshness for household fabrics

Potential applications in body armour and exoskeletons.

11th August 2021

Innovation in Textiles

|

Singapore & California

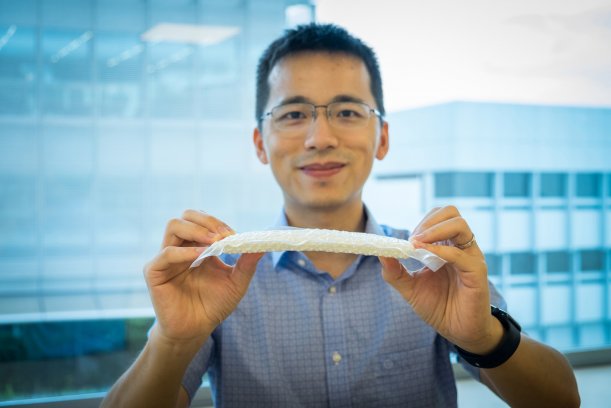

A new type of ‘chain mail’ fabric that is flexible like cloth but can stiffen on demand has been developed by scientists from Nanyang Technological University in Singapore and the California Institute of Technology (Caltech).

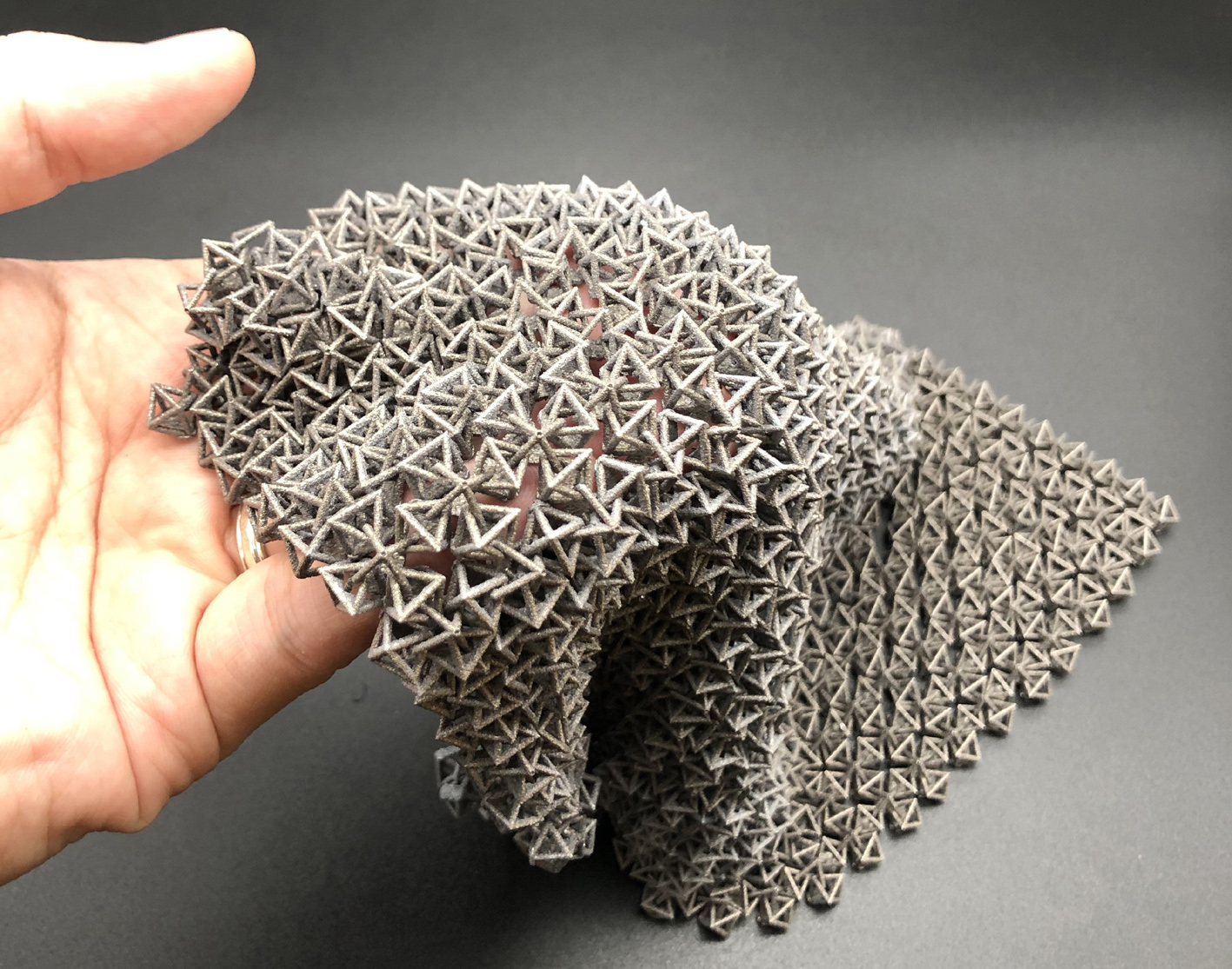

The lightweight fabric is 3D-printed from nylon plastic polymers and comprises hollow octahedrons – a shape with eight equal triangular faces – that interlock with each other.

When the soft fabric is wrapped within a flexible plastic envelope and vacuum-packed, it turns into a rigid structure that is 25 times stiffer or harder to bend than when relaxed. The physical principle behind it is called “jamming transition”.

It is believed these new ‘wearable structured fabrics’ could pave the way for smart fabrics that can harden to protect a user against an impact or when additional load-bearing capacity is needed. Potential applications include bullet-proof or stab-proof vests, configurable medical support for the elderly, and protective exoskeletons for high-impact sports or workplaces like construction sites. It could also lead to a new platform technology with applications in medical and robotic systems.

“An engineered fabric that is lightweight and tuneable – easily changeable from soft to rigid – can be used, for example, to address the needs of patients and the ageing population, to create exoskeletons that can help them stand, carry loads and assist them with their daily tasks,” said Nanyang assistant professor Wang Yifan, who started the research as a post-doc at Caltech. “Inspired by ancient chain mail armour, we used plastic hollow particles that are interlocked to enhance our tuneable fabrics’ stiffness. To further increase the material’s stiffness and strength, we are now working on fabrics made from various metals, including aluminium, which could be used for larger-scale industrial applications requiring higher load capacity, such as bridges or buildings.”

Jamming transition

In jamming transition, aggregates of solid particles switch from a fluid-like soft state to a solid-like rigid state, with a slight increase in packing density. However, typical solid particles are usually too heavy and do not provide enough tensile resistance for wearable applications.

The researchers designed structured particles – where each particle is made of hollow frames in the shape of rings, ovals, squares, cubes, pyramids and different shapes of octahedrons that are then interlocked together. These structures, known as ‘topologically interlocked structures’, can then be formed into chain mail fabric that has a low density and yet high tensile stiffness, using 3D printing technology to print them as a single piece.

The researchers then modelled the number of average contact points per particle and how much each structure will bend in response to the amount of stress applied. The team discovered that by customising the particle shape, there was a trade-off between how much weight the particles will have versus how much the fabric can bend, and how to balance the two factors.

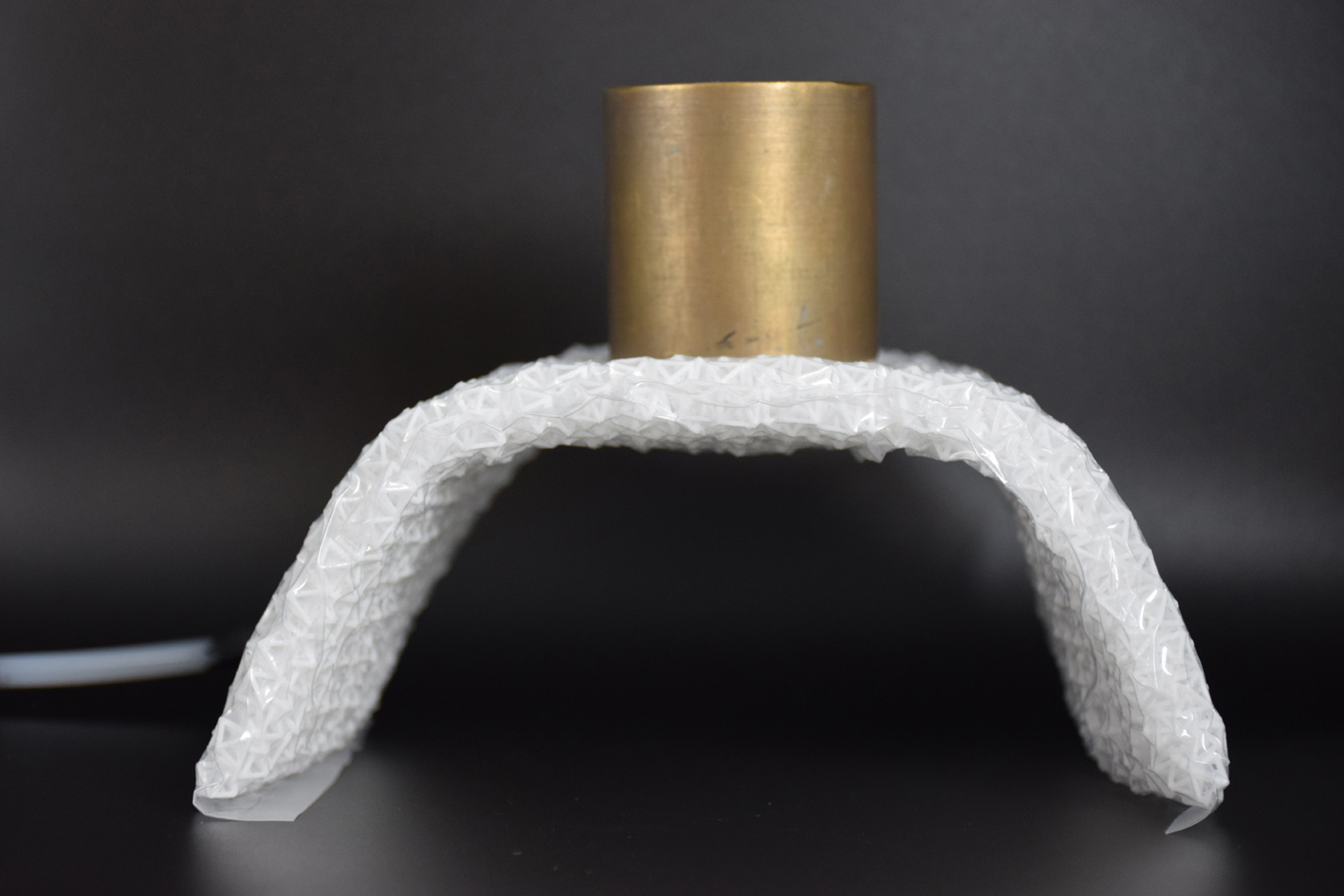

To add a way of controlling the stiffness of the fabric, the team encapsulated the chain mail fabric in a flexible plastic envelope and compacted the fabrics using a vacuum, which applies pressure from the outside. The vacuum pressure increases the packing density of the fabric, causing each particle to have more contact with its neighbours, resulting, for the octahedron-based fabric, in a structure that is 25 times more rigid. When formed into a flat, table-shaped structure and vacuum-locked in place, the fabric could hold a load of 1.5kgs – more than 50 times the fabric’s own weight.

In another experiment, the team dropped a small steel ball (30 grams, measuring 1.27cm in diameter) onto the chain mail at three metres per second. The impact deformed the fabric by up to 26mm when it was relaxed, but by only 3mm when it was stiffened – a six times reduction in penetration depth.

To show the possibilities of their fabric concept using different source material, the team 3D-printed the chain mail using aluminium and demonstrated that it has the same flexibility and ‘soft’ performance as nylon when relaxed and yet it can also be ‘jammed’ into structures that are much stiffer compared to nylon due to aluminium’s higher stiffness and strength.

Moving forward, the team is looking to improve the material and fabric performance of the chain mail and to explore more methods of stiffening it, such as through magnetism, electricity or temperature.

Business intelligence for the fibre, textiles and apparel industries: technologies, innovations, markets, investments, trade policy, sourcing, strategy...

Find out more