French push for face mask independence

Mask meets the new ASTM standard for filtration and breathability.

15th April 2021

Innovation in Textiles

|

Raleigh, NC, USA

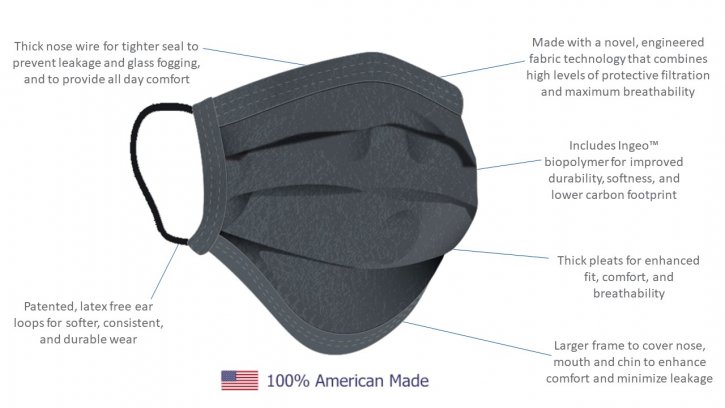

Aries, based in Raleigh, North Carolina, is launching the Aries Work Week Barrier Face Covering, which meets the newly released ASTM standard F3502-21 at Level 2 (high performance) for both filtration and breathability.

The Aries Work Week Barrier Face Covering provides business operators with a third-party tested and verified barrier face covering that can protect workforces for an entire 40-hour work week.

“Companies want to return to work, and employees want to be able to breathe freely and be comfortable through an eight-hour workday,” said Chris Evans, CEO of Aries USA. “The Aries Work Week Barrier Face Covering is one of the first to comply with the ASTM 3502 standard, delivering both filtration and breathability at Level 2, which are high performance standards. Our masks carry the ‘meets ASTM 3502’ label on each product, guaranteeing that users are getting the performance they need and expect.”

The recently announced ASTM F3502 standard sets guidelines with which buyers can evaluate face coverings. The new standards set base-level requirements for protection (particulate filtration efficiency), comfort and breathability (air flow resistance), and potential for reuse.

The standard was created in a joint effort by ASTM International, the National Personal Protective Technology Laboratory (NPPTL), as well as industry and academic experts.

The Work Week Barrier Face Covering is manufactured with Captur, an engineered fabric technology combining nonwoven polypropylene and Ingeo biopolymer to provide a high level of protective filtration combined with maximum breathability.

The fabric was developed in response to the ongoing supply chain constraints for meltblown fabric, which is typically used in medical masks and contributed to the mask shortages. Meltblown fabric is often an important component of medical masks because it has an electrostatic charge that captures sub-micron particles, increasing the filtration capabilities. Because Captur’s unique manufacturing process also adds an electrostatic charge, a meltblown layer is not needed, resulting in a single-layer mask with both high filtration and breathability.

Business intelligence for the fibre, textiles and apparel industries: technologies, innovations, markets, investments, trade policy, sourcing, strategy...

Find out more