Autonomous safety for the Nuro

Autoliv, a global leader in automotive safety systems, will invest around $50 million in a textile centre in China, making it more competitive by reducing supplier costs through vertical integration. “The textile centre is very important to meet the increasing demand for airbags in China and other Asian markets,” said Jan Carlson, President and CEO of Autoliv Inc. “In addition, the textile centre will increase our level of in-house component sourcing and enable standardised designs in Asia region and globally, while shortening and streamlining our supply chain,” he added.

4th July 2013

Innovation in Textiles

|

Stockholm

Autoliv, a global leader in automotive safety systems, will invest around $50 million in a textile centre in China, making it more competitive by reducing supplier costs through vertical integration.

“The textile centre is very important to meet the increasing demand for airbags in China and other Asian markets,” said Jan Carlson, President and CEO of Autoliv Inc. “In addition, the textile centre will increase our level of in-house component sourcing and enable standardised designs in Asia region and globally, while shortening and streamlining our supply chain,” he added.

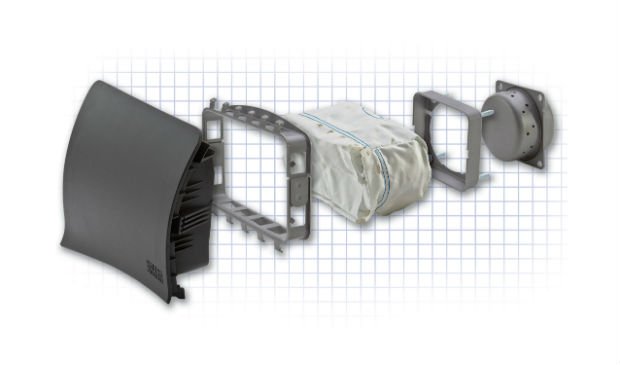

The textile centre will consist of a weaving plant, an airbag cushion plant and a development centre for airbag cushions and textiles.

The weaving plant will focus on manufacturing textiles for airbags using Autoliv’s patented ‘one-piece-woven’ (OPW) technology. By using this efficient technology, the airbag cushions can be almost ready-made on the weaving loom. This plant will have a floor space of more than 8,000 square meters and have around 150 employees.

In addition a separate building of similar size will be constructed at the same site for airbag cushion manufacturing. This is a relocation from an existing site in the Shanghai area, allowing the current site to expand its airbag module manufacturing capacity. This airbag cushion operation will have around 1000 employees.

When the project is completed, in line with its strategy of globalising products and processes, Autoliv will have in house manufacturing of OPW in all of its three regions, Europe, Americas, Asia, produced according to the same process. The plant will also produce woven fabric for traditional ‘cut and sewn’ cushions.

Globally, in 2012, Autoliv produced 70 million airbag cushions in-house and purchased 40 million from external suppliers for its total production of 110 million complete airbags.

In addition a co-located development centre for airbag cushion and textile will be created. It will focus on standardised designs for the Asia region.

Business intelligence for the fibre, textiles and apparel industries: technologies, innovations, markets, investments, trade policy, sourcing, strategy...

Find out more