SPGPrints ready for Barcelona

Finding common cause between the manufacturing methods for flexible electronics and textiles.

1st July 2021

Innovation in Textiles

|

North Carolina, USA

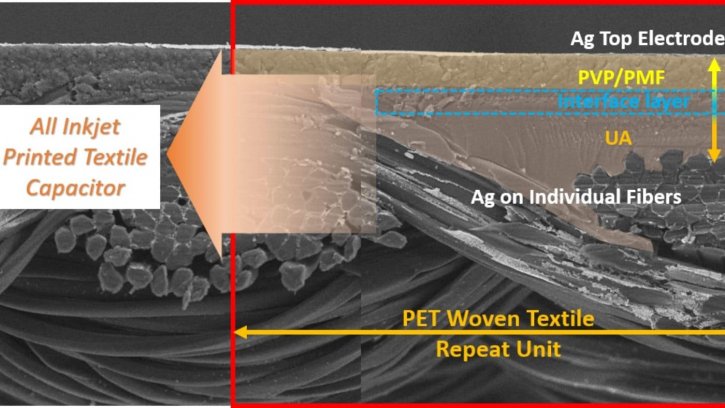

North Carolina State University researchers have printed layers of electrically conductive inks onto polyester fabrics to make e-textiles that could be used in the design of future wearable devices.

Since the printing method can be carried out at room temperature and in normal atmospheric conditions, the researchers believe inkjet printing could offer a simpler and more effective method of manufacturing e-textiles. In addition, techniques common in the flexible electronics industry could be extended to textile manufacturing. The work was reported in the journal ACS Applied Materials & Interfaces.

“Inkjet printing is a rapidly advancing technology that’s used in flexible electronics to make films used in cellphone displays and other devices,” said Jesse S. Jur, professor of textile engineering, chemistry and science at NC State. “We think this printing method – which uses materials and processes that are common in both the electronics and textiles industries – also shows promise for making e-textiles for wearable devices.”

A Fujifilm Dimatix inkjet printer was used to create a durable and flexible e-textile material. Part of the challenge was to find the right composition of materials to ensure the liquid ink would not seep through the porous surface of the textile materials and lose its ability to conduct electricity.

“Printing e-textiles has been a very big challenge for the e-textile industry,” said Inhwan Kim, a former graduate student at NC State. “We wanted to build a structure layer by layer, which has not been done on a textile with inkjet printing before. It was a big struggle for us to find the right material composition.”

Layers of electrically conductive silver ink were printed like a sandwich around two liquid materials– urethane-acrylate and poly(4-vinylphenol) – which acted as insulators. After printing, the surface of the material was monitored using a microscope. The chemical properties of the insulating materials, as well as of the textile yarns, proved important in maintaining the ability of the liquid silver ink to conduct electricity and prevent it from penetrating through the porous fabric.

“We wanted a robust insulation layer in the middle, but we wanted to keep it as thin as possible to have the entire structure thin, and have the electric performance as high as possible,” Kim said. “If fabrics are too bulky, people will not want to wear them.”

The electrical performance of the e-textile was retained after more than 100 cycles of bending and work will continue on improving the electrical performance compared to e-textiles created using methods that require special facilities and atmospheric conditions, as well as on increasing breathability.

“We were able to coat the ink on the fabric in a multi-layer material that’s both durable and flexible,” Kim said. “The beauty of this is, we did everything with an inkjet printer – we didn’t use any lamination or other methods.”

Business intelligence for the fibre, textiles and apparel industries: technologies, innovations, markets, investments, trade policy, sourcing, strategy...

Find out more