Saral StretchSilver 500 ideal for wearables

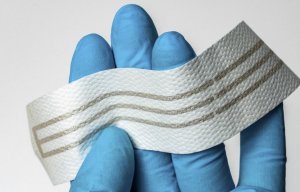

The interconnected net of nanoscale fibres is stacked in layers.

12th April 2022

Innovation in Textiles

|

Stanford, CA, USA

After creating a new type of elastic light-emitting polymer, Stanford University chemical engineers have developed high-brightness, stretchy colour wearable displays.

Today’s displays – which are flat, rigid and fragile – lack the ability to reshape to interactively respond to users, but chemical engineer Zhenan Bao and her research team have shown the proof of principle of a stretchable, potentially reshapable display in a new paper published in Nature.

Their new high-brightness elastic light-emitting polymer functions like a filament in a lightbulb and the group’s resulting display has a maximum brightness at least two times that of a cellphone and can be stretched up to twice its original length without tearing.

“Stretchable displays can allow a new way of interactive human-machine interface,” said Bao. “We can see the image and interact with it, and then the display can change according to our response.”

Most light-emitting polymers are stiff and crack when stretched. Scientists can increase their flexibility by adding elastic insulating materials, such as rubber, but these additives decrease electrical conductivity,which requires the polymer to use a dangerously high voltage to generate even dim light.

About three years ago, however, post-doctoral scholar Zhitao Zhang discovered that a yellow-coloured light-emitting polymer called SuperYellow not only became soft and pliable but also emitted brighter light when mixed with a type of polyurethane.

“If we add polyurethane, we see SuperYellow form nanostructures,” said Zhang. “These nanostructures are really important. They make the brittle polymer stretchable, and they make the polymer emit brighter light because the nanostructures are connected like a fishnet.”

Unlike adding rubber, the interconnected net of nanoscale fibres don’t inhibit electricity flow. After this discovery, the group also created elastic red, green and blue light-emitting polymers.

With stretchable light-emitting polymers now available, the group needed to layer together the remaining ingredients of an electronic display.

“It was really challenging to figure out the right materials to use,” Bao said. “Electronically, they have to match each other to give us high brightness. But then they also need to have similarly good mechanical properties to allow the display to be stretchable. And finally, for the fabrication, Zhitao had to figure out a way to stack the layers together so that the process will not degrade the brightness.”

The final display contains seven layers. Two outer layers are substrates that encapsulate the device. Moving inward are two electrode layers, each followed by charge transporting layers. Finally, the light-emitting layer sits sandwiched in the centre.

When electricity runs through the display, one electrode injects positive charges into the light-emitting layer while the other injects negatively charged electrons into it. When the two types of charges meet, they bond and go into an energetically excited state. Almost immediately after, the state returns to normal by producing a photon – a particle of light.

The resulting all-polymer film can be adhered to an arm or finger and doesn’t rip during bending or flexing. This will allow wearable trackers to have their display directly attached to the skin.

Bao sees a variety of additional potential uses for a stretchable display. It could be used, for example, to produce reshapable interactive screens or even form three-dimensional landscapes on a map.

Business intelligence for the fibre, textiles and apparel industries: technologies, innovations, markets, investments, trade policy, sourcing, strategy...

Find out more