Pushing the boundaries of fabric inspection

The leading Swiss software firm is aiming to revolutionize the industry by commercializing the first Deep Learning-based image analysis solution dedicated to the machine vision market.

27th August 2015

Innovation in Textiles

|

Villaz-St-Pierre, Switzerland

“With ViDi Suite, the automatic inspection of complex pattern fabrics is now extremely simple,” Olivier Despont, Business Development at ViDi says. The software algorithm trains itself on a set of known good samples to create its reference model and no tedious software development is said to be required.

“Once this training phase is completed, the inspection is ready to go. Defective areas of the fabric can quickly be identified and reported. Best of all, there is no need for extensive defect libraries,” Olivier Despont adds.

APPLICATIONS

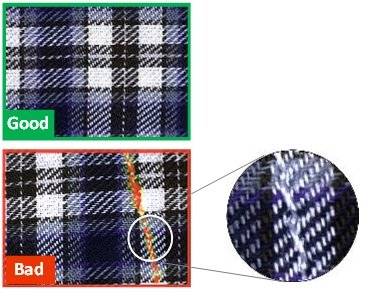

Yarn dye plaid

For this first woven fabric, the company provided its ViDi red tool with a representative set of good samples for the system to learn by itself - completely unsupervised, the weaving pattern, yarn properties, colours and tolerable imperfections.

For this first woven fabric, the company provided its ViDi red tool with a representative set of good samples for the system to learn by itself - completely unsupervised, the weaving pattern, yarn properties, colours and tolerable imperfections.

After the training phase was completed, the inspection was able to quickly identify defects like the ones shown on the right.

Top: Unexpected stitching

Bottom: Weaving weft float

The software required only 9 good images of the fabric and training took only 4 minutes, on a single GPU.

Watch the live example in the video below…

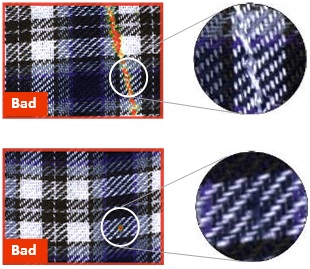

Yarn dye stripes

Yarn dye stripes

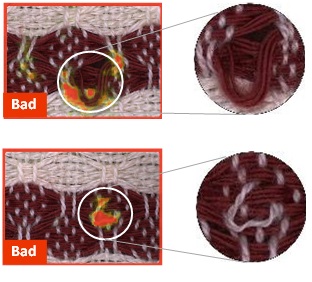

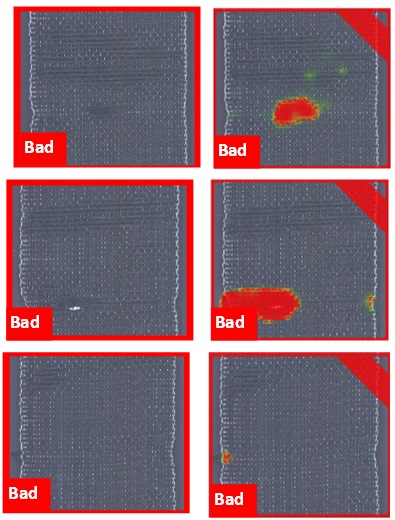

On this second set of fabrics, just as for the previous set, ViDi’s red tool learns by itself, a model of the complex knitting pattern from a collection of randomly selected good samples.

During the inspection phase, the red tool reports defective areas of the fabric like the ones shown at the right: knitting loops in warp and weft.

Coarsely woven narrow fabric

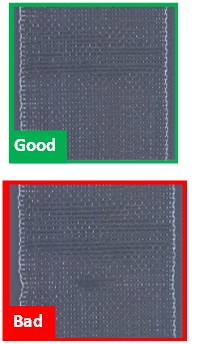

In this application, ViDi customer Fibrescan Ltd. (www.fibrescan.co.uk) uses ViDi Suite to inspect coarsely woven fabric at a manufacturing speed of 60m/min in real time.

In this application, ViDi customer Fibrescan Ltd. (www.fibrescan.co.uk) uses ViDi Suite to inspect coarsely woven fabric at a manufacturing speed of 60m/min in real time.

After learning from around 40 images of good samples, ViDi Suite masters the challenge of distinguishing unacceptable defects from tolerable naturally occurring fabric variations (see examples right).

The complete application (training & learning included) was performed in approximately 15 minutes. Fast image processing (less than 50 ms/image) enables Fibrescan’s machines to perform inline inspections.

“For textile inspection, this represents a breakthrough technology,” Charles Schofield, CEO of Fibrescan says.

BENEFITS

According to ViDi, its novel approach brings human visual inspection performances to automatic textile quality control equipment. It radically differs from traditional Machine Vision solutions since it is:

Self-Learning: Textile inspections were conducted without involving any pre-defined defect library. Instead, the system learns all by itself, completely unsupervised, the weaving pattern, yarn properties, colours, and tolerable imperfections

Self-Learning: Textile inspections were conducted without involving any pre-defined defect library. Instead, the system learns all by itself, completely unsupervised, the weaving pattern, yarn properties, colours, and tolerable imperfections

Human-like: It outperforms the best quality inspectors in term of accuracy, testing consistency, and speed

Powerful: In both cases, learning from the known good sample was achieved in less than 10 minutes. Most types of textile manufacturing defects can be identified at each stage of textile processing (ginning, spinning, cutting, weaving/knitting, pre-treatment, dyeing/printing, finishing, and stitching)

Thanks to ViDi Suite:

“Are you ready to join the revolution,” Says Olivier Despont?

“Visit our website www.vidi-systems.com and challenge us, or come visit us at ITMA 2015 in Milano (booth # H3-D104).”

Further information

Contact: Olivier Despont

Business Development

ViDi Systems SA

Z.I. du Vivier 22

CH-1690 Villaz-St-Pierre

Tel. + 41 26 653 72 30

Fax + 41 26 653 71 81

Business intelligence for the fibre, textiles and apparel industries: technologies, innovations, markets, investments, trade policy, sourcing, strategy...

Find out more