Web Industries new printing capability enhances product appeal

Web Industries, a leader in outsource converting and manufacturing solutions, has expanded its printing capacity through equipment upgrades at its facility in Dallas, Texas.

17th January 2013

Innovation in Textiles

|

Marlborough, MA

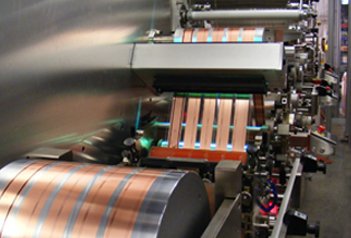

The upgrades add high-speed flexographic printing with tight dimensional pattern registration and precision inline slitting to the facility’s existing flexible material converting assets, giving Web Dallas the ability to print and convert large rolls of material in a single operation.

The printer improvements allow Web Dallas to offer high speed, wide web, one colour flexo printing that can hold complex graphics without image bleed-through on nonwovens as light as 10gsm and on papers.

The 60" press at Dallas joins the 90" press at Web Industries Fort Wayne in providing customers with the opportunity to print registered and non-registered patterns and slit inline to multiple widths depending on end-use needs, eliminating unnecessary manufacturing steps and reducing overall costs.

“There are many market applications where complex printing registration is critical to the finished product’s branding. Our in-depth experience and expertise in printing on nonwovens and our 90" and 60" presses provide a combination of scale and precision that is a good fit for our customers’ varying substrate widths and geographical needs,” said Claudio Hanna, Web Industries’ Director of Sales for Consumer Products.

“When you combine that capacity with our inline converting processes like slitting, spooling, and lamination, we offer cost-effective manufacturing solutions that provide value to our customers while allowing them to really deliver a graphically differentiated product.”

The company says the printing capability expansion at Dallas, combined with recent equipment upgrades at Fort Wayne, will keep it positioned as the preeminent outsource converting and manufacturing partner for home, personal care, and medical product companies.

For over 40 years, Web Industries has been a leader in providing contract manufacturing solutions to companies facing speed-to-market, capacity, and product or supply chain complexity problems. The company applies its precision slitting, large-format spooling, flexographic printing, hot melt lamination, ultrasonic embossing, and complete supply chain management technologies to get its partner’s products into the marketplace quickly, efficiently, and economically.

Business intelligence for the fibre, textiles and apparel industries: technologies, innovations, markets, investments, trade policy, sourcing, strategy...

Find out more