Conquering Nazaré’s waves with flax

Transmitters work at a different frequencies and require little computing power to determine where the sound waves have changed.

29th May 2025

Innovation in Textiles

|

Zurich, Switzerland

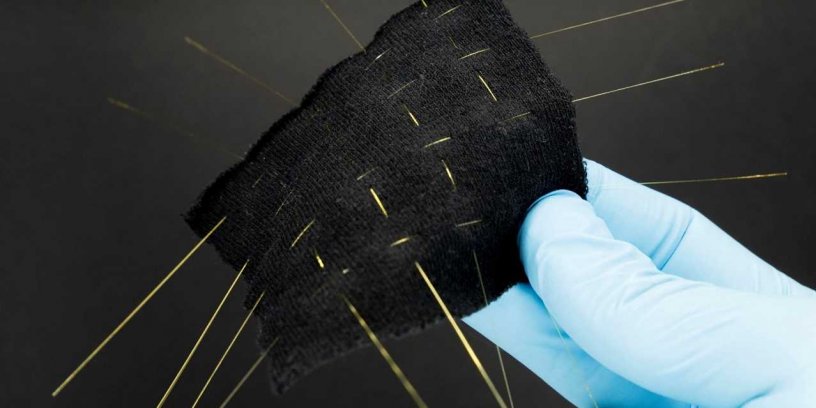

Researchers at ETH Zurich in Switzerland led by Daniel Ahmed, Professor of Acoustic Robotics for Life Sciences and Healthcare, have developed new smart fabrics for touch, pressure and movement measurement, which instead of electronics are based on acoustic waves passed through glass fibres.

This makes the measurements the fabrics can carry out more precise and the textiles lighter, more breathable and easier to wash.

“Our SonoTextiles are also inexpensive because we use readily available materials and the power consumption is very low,” says Ahmed. “While research has already been conducted into smart textiles based on acoustics, we are the first to explore the use of glass fibres in combination with signals that use different frequencies.”

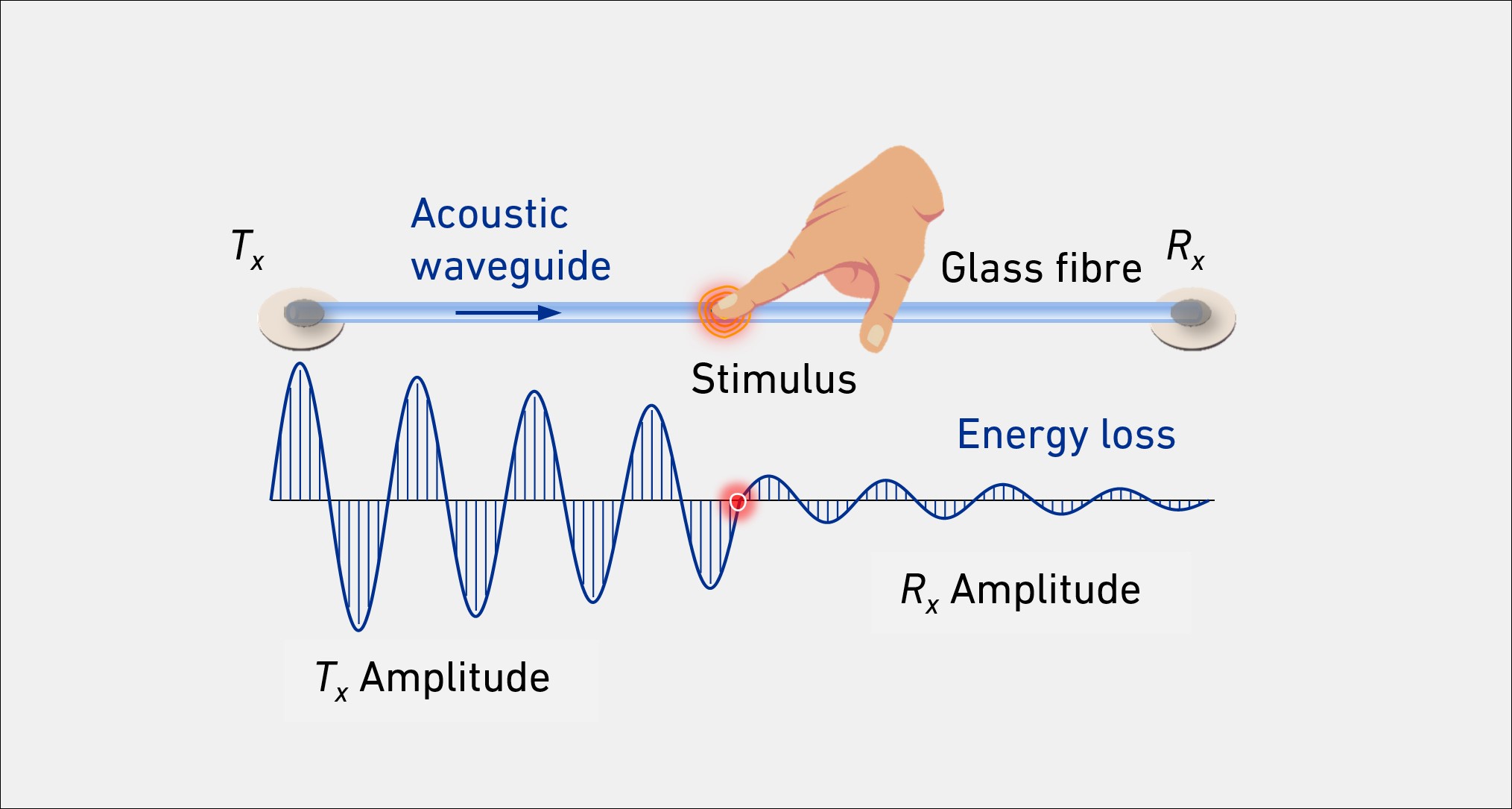

The glass fibres are woven into a fabric at regular intervals with small transmitters that emit sound waves at one end of each of them. The other end of each is connected to a receiver that measures whether the waves have changed.

Each transmitter works at a different frequency which means it requires little computing power to determine which fibre the sound waves have changed on. Previous smart textiles often struggled with data overload and signal processing issues, since each sensor location had to be evaluated individually.

“In the future, the data could be sent directly to a computer or smartphone in real time,” says Ahmed.

When a glass fibre moves, the length of the acoustic waves passing through it changes as they lose energy. In the case of a T-shirt, this can be caused by body movement or even breathing.

“We used frequencies in the ultrasonic range of around 100 kilohertz which is well beyond the range of human hearing, which is between 20 hertz and 20 kilohertz,” explains project researcher Yingqiang Wang.

Potential uses

The researchers have shown that their concept works in the lab and in the future, SonoTextiles could be used in a variety of ways

As a shirt for example, they could monitor the breathing of asthma patients and trigger an alarm in an emergency, while in sports training and performance monitoring, athletes could receive real-time analysis of their movements, to optimise their performance and prevent injuries.

The textiles also have potential for sign language – gloves with this technology could simultaneously translate hand movements into text or speech. Virtual or augmented reality environments are other potential end-use avenues.

“SonoTextiles could even measure a person’s posture and improve their quality of life as an assistive technology,” suggests research team member Chaochao Sun. “People who want to improve their posture could receive targeted corrective feedback. The textiles could also indicate when a wheelchair user needs to change position to prevent pressure ulcers.”

Although the everyday usability of SonoTextiles is potentially very high, Ahmed adds that there is still room for improvement in terms of practical application.

Glass microfibres worked well as sound conductors in the lab, but they could potentially break in everyday use.

“The beauty is that we can easily replace the glass fibres with metal because sound also propagates effectively through it,” says Ahmed in conclusion. “We would like to expand our research in this direction and also into other applications.”

Business intelligence for the fibre, textiles and apparel industries: technologies, innovations, markets, investments, trade policy, sourcing, strategy...

Find out more