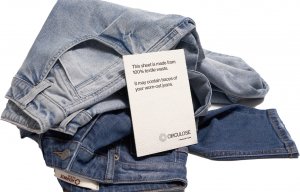

Circulose in 50% blend for denim

AGI now recycles 4.4 million gallons of water each month – enough to treat a million pairs of jeans.

2nd March 2021

Innovation in Textiles

|

Karachi, Pakistan

Refresh is the name of the latest jeans collection from AGI Denim – reflecting the company’s significant reduction in water consumption.

The company has just opened a new cotton fibre spinning plant and a denim mill at its complex in Karachi, Pakistan.

“Over the years we’ve gone through a series of backward integration steps to become fully vertical,” said executive director Ahmed Javed, speaking at the recent 24 Flash Kingpins. “In our latest expansion we revisted every step of the production processes in order to make resource savings.”

Innovations have included the installation of proprietary robotics for garment finishing, but the most attention has been paid to water savings.

While we can’t control how much water cotton needs to grow, we can rethink the way we use it in our factory

“Pakistan is one of the largest cotton-producing companies in the world and we’re fortunate that the type of cotton that is grown here is well suited to denim production and also helps us lower our carbon footprint, with everything done in close proximity,” Javed said. “In the lifecycle of a pair of denim jeans, however, cotton fibre production contributes 68% of water consumption. While we can’t control how much water cotton needs to grow, we can rethink the way we use it in our factory.”

Refresh-branded denims are produced with 100% recycled water at every process step, as a result of the company’s new wastewater treatment.

The plant puts production wastewater through a series of steps beginning with equalisation, followed aeration and concluding with sedimentation. It travels through filtration and ultrafiltration systems before being subjected to an activated carbon system and finally a reverse osmosis system to reduce any dissolved salts.

AGI now recycles 300,000 gallons of water daily, the equivalent of 4.4 million gallons of water each month – enough to wash one million pairs of jeans.

“We aim to recycle a million more gallons daily by 2022, so that reprocessed water represents 85% of our fresh water needs,” Javed concluded.

Business intelligence for the fibre, textiles and apparel industries: technologies, innovations, markets, investments, trade policy, sourcing, strategy...

Find out more