Timely debut for Wastex

Opinion

Aim is to achieve annual fibre-to-fibre recycling of 2.5 millions tons of Europe’s textile waste by 2030.

5th July 2022

Adrian Wilson

|

Frankfurt, Germany

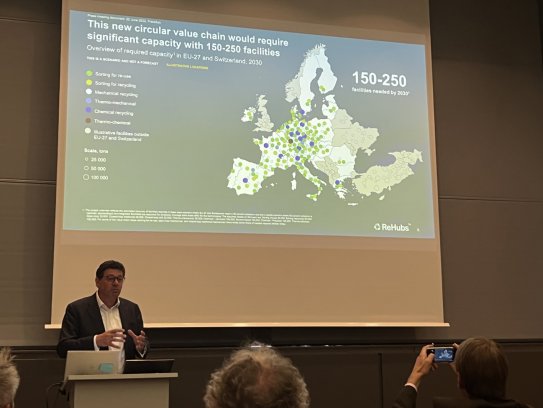

The ambitious ReHubs initiative is planning the establishment of between 150-250 dedicated new recycling centres to be established in the next few years – each with annual capacities of between 50-100,000 tons.

ReHubs is being initiated by Euratex – the Brussels-based organisation which represents around 154,000 companies employing 1.47 million workers in the European textiles and clothing industries.

The aim is to achieve the annual fibre-to-fibre recycling of 2.5 millions tons of Europe’s textile waste by 2030 in response to the separate collection of textile waste, which will become mandatory for all EU member states on January 1st 2025.

Europe has a 7-7.5 million tons annual textile waste problem, of which only 30-35% is collected today, and very little of that is returned to fibre form to enable true value retention.

The initiative has the backing of a business council of key companies spanning the entire textile supply chain – from fibre leaders like Indorama Ventures and Lenzing to leading sports brand Decathlon and fashion giant Inditex

Cost

At a press conference during Techtextil 2022 in Frankfurt held on June 22nd, Robert van de Kerkhoff, Lenzing’s chief commercial officer and president of CIRFS, the European manmade fibres association, put the estimated investment cost of the initiative at between €6-7 billion, largely to scale up sufficient sorting and processing infrastructure.

Once matured and scaled, however, it is envisaged the new industry would be profitable, with a total annual market value of between €6-8 billion, generating around 15,000 direct new jobs by 2030 and resulting in significant near-shoring.

“Sooner or later, textile materials become non-reusable waste, making recycling a must once all other options are exhausted,” van de Kerkhoff said. “A supply chain requires sorting for both re-use and recycling and a range of mechanical and chemical recycling solutions to be established.

Turning point

“Recycling is not yet mature, but we may be at the brink of a turning point as different technologies race to scale. We are aiming for the fibre-to-fibre recycling of between 18-26% of Europe’s total textile waste by 2030, but success is not a given. To reach critical scale, real collaboration and transition funding is required, along with investments at company level and a huge public sector push.”

The first immediate project will examine current sorting technologies to accurately identify materials for subsequent circular recycling processes. Led by Texaid AG, of Schattdorf, Switzerland, the aim is to establish the first 50,000 ton facility by the end 2024.

“With the adoption of the EU Textile Strategy in March this year, the European Commission has launched a very ambitious journey that will change the nature of our industry,” said Euratex president Alberto Paccanelli. “It calls for more focus on sustainability and durability, more transparency within the supply chain, more communication with the consumer and also a level playing field for our European companies, with increased investment in innovation, digitalisation and skills development.

“This is a very ambitious agenda which needs to result in a more resilient European textile industry. The coming two years will be critical to translate that vision into specific legislation and concrete programmes.”

Business intelligence for the fibre, textiles and apparel industries: technologies, innovations, markets, investments, trade policy, sourcing, strategy...

Find out more