Promoting good sleep with Outlast

Outlast technology, originally developed for NASA to protect astronauts from temperature fluctuations in space, now will be utilised in a new blend from PCM viscose fibres and polyester fibre balls for use in apparel.

12th June 2014

Innovation in Textiles

|

Heidenheim

Outlast Technologies, a market leader for temperature regulating phase change materials (PCMs), has introduced Spherix, a new blend from PCM viscose fibres and polyester fibre balls that is said to offer dynamic climate regulation and added comfort and can be used in apparel.

The new Outlast filling material is soft and breathable, thus offering the advantage of a dynamic heat management, the company reports. The fibre balls are said to provide lightness, volume and loft, while the PCM viscose fibres account for the temperature management function.

According to Outlast, the company has already successfully gained experience in the bedding market with filling materials while being the pioneer in launching the first PCM polyester fibrefill produced on a large scale. For the apparel market Outlast took a further step and combined fibre balls with a short cut fibre.

The innovative fibre ball fibre (FBF) blend consists of 30% PCM viscose short cut fibres and 70% standard polyester balls. “We are working with a highly filled PCM viscose fibre,” explained Martin Bentz, Managing Director of Outlast Europe. “With 7 dtex the diameter of the viscose fibre is quite high, so we can reach an approximately four times higher performance compared to our standard PCM viscose fibre.”

The new PCM fibrefill regulates the climate proactively – in contrast with other technologies that only wick away humidity, Outlast technology is said to manage the heat while controlling the production of moisture before it begins, so less humidity is produced inside the apparel.

While Outlast technology is often seen as a winter theme, Spherix opens a new addition for summer. Light outdoor wear or even summer quilted jackets will also offer a comfortable temperature regulation with Spherix.

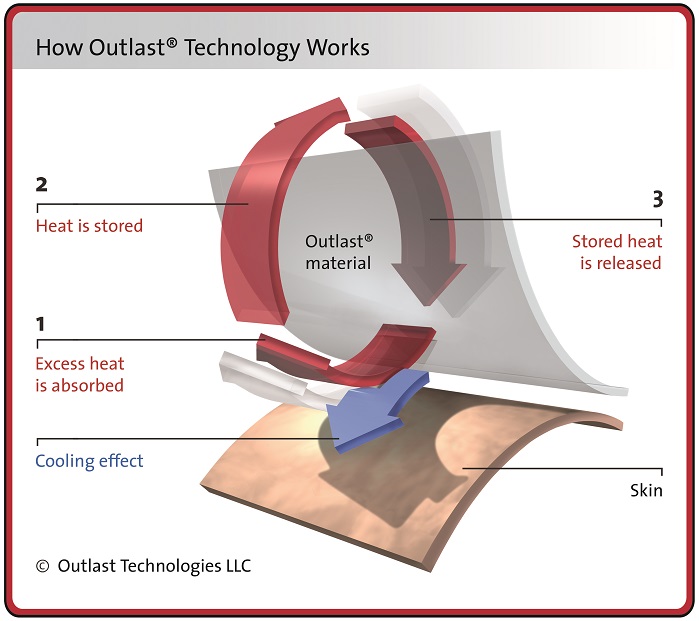

Outlast technology was originally developed for NASA to protect astronauts from temperature fluctuations in space. It utilises phase change materials (PCM) that absorb, store and release heat for optimal thermal comfort.

The PCMs have the capacity to absorb, store and release excess heat. This gives any product containing Outlast technology the ability to continually regulate skin’s microclimate. As the skin gets hot, the heat is absorbed, and as it cools, that heat is released.

Outlast technology will proactively manage heat while controlling the production of moisture before it begins.

Outlast Technologies LLC, a privately held US corporation, is the leader in phase change materials and applications.

For over 20 years, Outlast has been committed to the development of new fibres, fabrics and coatings incorporating phase change materials, expanding the use of Outlast technology across more than 300 brands and a multitude of products in apparel, footwear, bedding, packaging and labels, and accessories.

Business intelligence for the fibre, textiles and apparel industries: technologies, innovations, markets, investments, trade policy, sourcing, strategy...

Find out more