SGL Group leads UK-funded research project

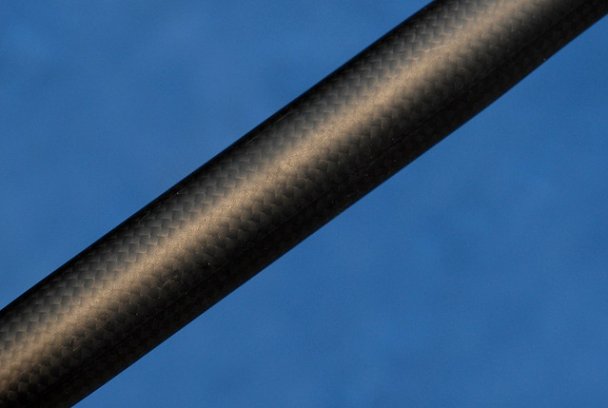

What if carbon fibres could be made of a renewable raw material instead of oil? With such a raw material as the wood based product lignin, the volume of production could increase considerably and more products could be manufactured in high-performing light-weight materials, according to the Swiss Textile College. The Swedish institute Innventia has been awarded a grant of SEK 3,400,000 by the Swedish Governmental Agency for Innovation Systems (VINNOVA) for two projects, which are expected to accelerate the development of new products from renewable resources.

26th March 2014

Innovation in Textiles

|

Zurich

What if carbon fibres could be made of a renewable raw material instead of oil? With such a raw material as the wood based product lignin, the volume of production could increase considerably and more products could be manufactured in high-performing light-weight materials, according to the Swiss Textile College.

The Swedish institute Innventia has been awarded a grant of SEK 3,400,000 by the Swedish Governmental Agency for Innovation Systems (VINNOVA) for two projects, which are expected to accelerate the development of new products from renewable resources.

The grant is a part of VINNOVA's focus on the development of test beds within the environmental technology area. At Innventia research activities have shown that it is possible to produce carbon fibres from lignin, which is a by-product in a kraft pulp mill.

The test bed Swedish lignin-based carbon fibre will expand the possibilities for establishing lignin as a raw material for carbon fibre production. In addition, the development of 3D packages of paper and board can also come true thanks to a new feasibility study at Innventia.

“The grant confirms our focus on carbon fibre from lignin. Within the frame of the project, we will also produce criteria for building a pilot facility for multifilament carbon fibre production. Thanks to our establishment of a consortium of parties along the whole value chain, from raw material producers to end users, and research institutes, we have now good potential to increase the availability of biobased carbon fibre,” said Marie Bäckström, the research leader within Biorefinery Processes and Products.

The industrial usage of carbon fibre is foreseen to increase by 2020. The Swiss Textile College believes carbon fibre composites can replace steel in cars and transport vehicles and reduce the weight and thereby the fuel consumption.

The need for new non-petroleum based raw material for carbon fibre production is huge. Lignin is a biobased, renewable material that is accessible in large quantities. The establishment of a test bed would accelerate the development of lignin into an established raw material for carbon fibre production.

In addition to the investment in a test bed for lignin-based carbon fibre, Innventia is granted SEK 400,000 to examine how the pilot plant, FEX, can be developed into a test bed for manufacture of highly stretchable paper and board products.

The idea is to enable testing in the future of new manufacturing concepts for paper that has to be extremely stretchable in both machine and cross direction, a quality that will make it possible to replace some of today's 3D packages in plastic, thereby reducing the amount of non-biodegradable plastic waste.

Business intelligence for the fibre, textiles and apparel industries: technologies, innovations, markets, investments, trade policy, sourcing, strategy...

Find out more