Scientists develop polar bear fur-inspired thermal textile

This research will help automotive suppliers to secure a competitive advantage in future by increasing comfort levels, saving energy and reducing development costs.

13th October 2014

Innovation in Textiles

|

Boennigheim

The government hopes that by 2020 there will be 20 million electric cars on Germany's roads. However, to make electric vehicles attractive to large parts of the population, one of the aspects that needs to be improved is their range, according to the Hohenstein Institute.

The key to this, researchers believe, is intelligent energy management, and this includes not only the drive technology and construction of the vehicle but also energy guzzlers, such as the air conditioning and interior heating systems. In electric cars, both of these have to operate from the power supply, at the expense of the vehicle's range.

In the light of this, scientists from the Hohenstein Institute, FILK, and IHD have been investigating the factors affecting the design of thermally optimised car seats. The aims of the project are to establish the theoretical principles behind heat transfer in seat covers, create a model of the processes involved in heat transfer and implement it in the design of improved seating.

The researchers are concentrating on using appropriate materials and combining them intelligently to provide a certain amount of passive climate control. They are not looking at active solutions, such as heating and cooling systems for seats. In the first phase of the project, the scientists from the three research institutions are studying the effect of the human body, and the heat it emits, on complex upholstery materials.

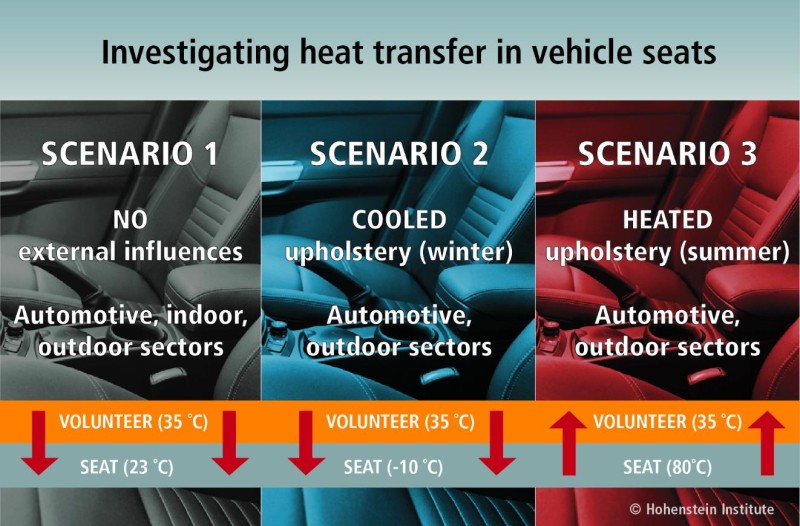

Firstly, they are considering different seat covers using standard and functional textiles. Secondly, they are basing their work on different usage scenarios. The constant factor is the feel-good temperature, which, with textile surfaces, is 23o C. Various different measuring methods can be used to derive quantitative load factors to describe the material or the combination of materials and their heat conduction properties in dry and moist conditions.

These reference values serve as the basis for simulating the processes involved in heat transfer. These simulations are carried out using what is called the Finite Element Method (FEM), a numerical procedure normally used, among other things, to calculate the dimensions of complex components and assemblies in engineering and vehicle manufacture. It can also be used to represent contradictory physical influences and their effects.

The simulations can then be used to calculate the combinations of materials and structural designs which would have the most positive effect on both heating and cooling behaviour.

This knowledge will help small and medium-sized automotive suppliers in particular to secure a competitive advantage for themselves in future by increasing comfort levels, saving energy and reducing development costs.

Business intelligence for the fibre, textiles and apparel industries: technologies, innovations, markets, investments, trade policy, sourcing, strategy...

Find out more