Techtextil presents intelligent fashion at Fashiontech

Opinion

A subtle shift is happening in discussions around smart materials and wearable technology, with a focus moving to developments in threads and yarn.

31st May 2019

Marie O'Mahony

|

Frankfurt

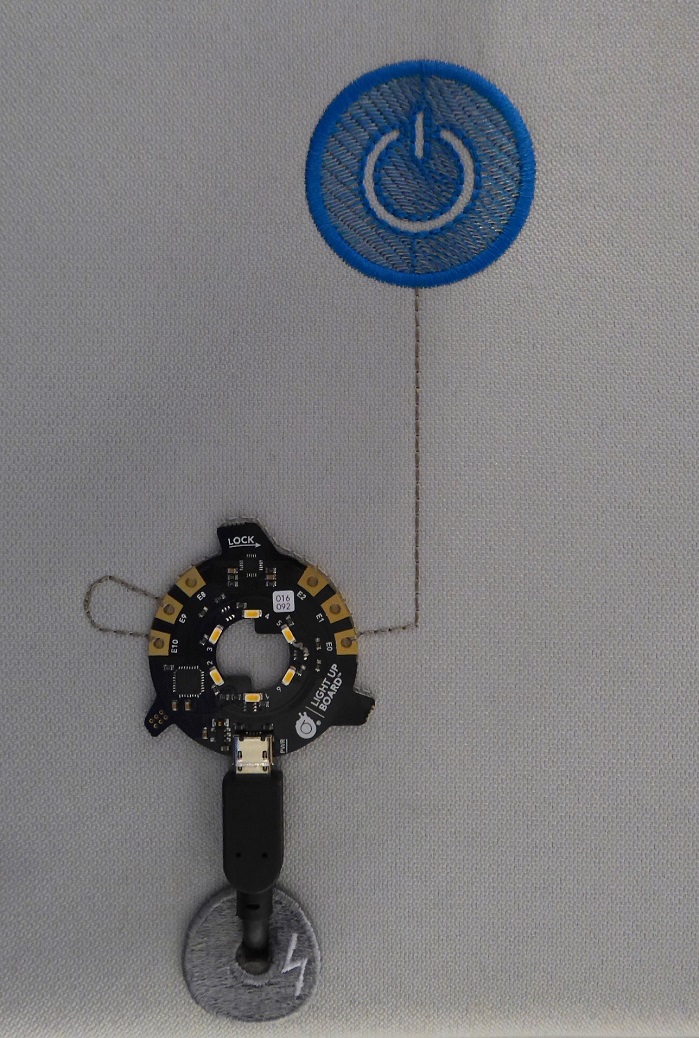

The AMANN Innovation Lab demonstrating different sensors used to activate lighting (l.to r.): conventional switch; touch; touch embroidered dimmer switch and proximity switch. © Marie O’Mahony

A subtle shift is happening in discussions around smart materials and wearable technology, with a focus moving to developments in threads and yarn and a concerted push to address some of the roadblocks to scaling up production – such as greater integration. The Techtextil trade show held from 4-7 May at Messe Frankfurt is a barometer of such shifts attracting researchers from academia as well as yarn, fabric and machine manufacturers and of course the brands that ultimately elect to bring the developments to market – or not.

The AMANN Group are well established as producers of high-quality sewing and embroidery threads. The AMANN Innovation Lab showed two years ago at Techtextil and again this year. Its focus is on smart materials showcasing their capability in conductive, sensing, lighting, heating and composites. Embedded in car seats the sensors are used to provide heat, illumination and the ability to recline. Products also include Sensorphil, a braided structure with integrated electrodes for detecting liquid. It is suited for continuous monitoring such as for elderly patients to detect the presence of urine or sweat. In another application, the sensor thread is incorporated into a shoe sole and it is capable of measuring temperature and humidity, important data for diabetic patients and their carers to have in real time.

New Textile Technologies (NTT) founded in 1999 has core competencies that include silk screen printing with silicone. Products include SensElast Connect for conductive textiles and SensElast 3-D and 3D Printing that allows for the 3D printing of filament on textile print. Liquid Wire working with SensElast Connect technology have developed a way of incorporating metal particles into the silicone rubber that can be painted, stencilled on to fabric or produced as a highly stretchable ‘noodle’ as demonstrated by Liquid Wire’s innovator Jorge Carbo.

The Teijin Frontier has launched a new line of sportswear and elderly and workwear monitoring garments incorporating what it terms wearable solutions. The company sees a requirement for clothing to be part of a Plan Do Check Action (PDCA) system for workwear, sportswear and elderly care. This brings with it with an increased need for real-time visualisation of movement and posture as well as heart rate. The Nanofront ultrafine fibre deploys an algorithm that visualises the difference between the actual motion of the wearer and their ideal motion during a particular activity. In garments, this could be used to optimise a golf swing or in workwear, to guard against injury by checking posture while lifting heavy goods for instance.

The AMANN Innovation Lab, embroidered touch switch. © Marie O’Mahony

Also in Asia, the Taiwan Textile Research Institute (TTRI) has grown from its origin as a textile testing centre when it was established in 1959, to today’s focus on research and development looking internationally as well as domestically for partnerships and markets. One of the areas that they are especially interested in is smart materials with products such as an RFID yarn that contains a chip every 16cm with another yarn embedding a flexible LED. MEC Addheat operate in Taiwan and manufacture in China producing a modular apparel heating system for use in apparel, gloves and footwear. It is designed to be lightweight, flexible and easy to install in brand designs and tested to fifty wash cycles. The largest market according to Eddie Chen, General Manager at MEC is workwear.

Researchers at the Institute of Textile Machinery (ITM), Technische Universitat Dresden are developing interactive fibre-elastomer composites with adjustable stiffness. Textile actuators and sensor networks based on shape memory alloys (SMA) for electroactive polymers are being embedded in a rubber matrix material. The filament yarns are based on electroactive polymers using a tricomponent structure comprised of a core, inner and outer sheath. In a second research project, a fibre reinforced plastic (FRP) composite includes a structurally integrated shape memory alloy (SMA) for use in high-precision kinematics. The research includes development of a hybrid yarn with a SMA core. This is then integrated into a hinge structured glass fibre with the modified thermosetting racing fabricated using a vacuum assisted resin infusion (VARI) technology. Both developments are looking to applications such as soft robotics and industrial grippers.

New Textile Technologies (NTT) showing silk screen printing with silicone. © Marie O’Mahony

The automotive industry is embracing e-textiles particularly for its luxury interiors. While many of the textile manufacturers were showcasing artificial leathers, there is still demand for real leather. ZSK are providing sewing and embroidery machines that can meet the demands of the leather market: “the biggest challenge is the perfect combination of sewing, embroidery and perforation”. This includes the use of conductive yarns with ZSK going so far as to produce a complete leather dashboard with controls using fully embroidered capacitive sensors.

While Wearable Technology is still attracting much of the attention for smart materials and systems, there is a noticeable focus on workwear where needs, benefits and environmental conditions are often more clearly defined than in some of the wellness markets. The automotive industry is undoubtedly taking shape, although the big-name manufacturers are reluctant to divulge plans in any great detail. As IoT continues to grow the opportunity and interest is there but the applications remain largely siloed, for the present at least.

Business intelligence for the fibre, textiles and apparel industries: technologies, innovations, markets, investments, trade policy, sourcing, strategy...

Find out more