Techtextil Innovation Award 2017 to honour new developments

FibeRio Technology Corporation – ‘The Force For Nanofibers’ - is introducing its nanofiber production equipment utilizing Forcespinning Technology to the textiles industry at the Techtextil Conference in Las Vegas, NV on March 15-17. The company recently launched their Cyclone L 1000 series laboratory equipment to enable research and development in forcespun nanofiber enhanced textiles. Â Forcespinning is an award winning technology that utilizes centrifugal

9th March 2011

Innovation in Textiles

|

McAllen, TX

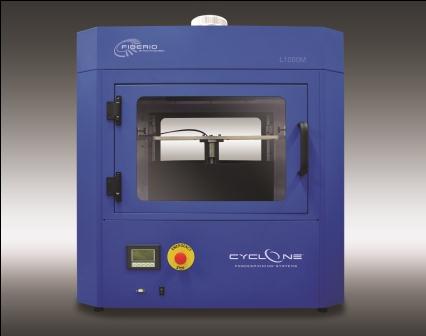

FibeRio Technology Corporation – ‘The Force For Nanofibers’ - is introducing its nanofiber production equipment utilizing Forcespinning Technology to the textiles industry at the Techtextil Conference in Las Vegas, NV on March 15-17. The company recently launched their Cyclone L 1000 series laboratory equipment to enable research and development in forcespun nanofiber enhanced textiles.

Forcespinning is an award winning technology that utilizes centrifugal force to spin nanofibers, nanowires, and nanorods. In 2010, the technology received the Silver Award at the World’s Best Technology Showcase and was recognized by the Society of Manufacturing Engineers as a 2010 Innovation That Could Change the Way You Manufacture.

“Forcespinning is a disruptive technology that enables a broader range of materials and surface functionalization in nanofiber production, which creates new materials properties that enable our customers to develop new products and gain a competitive advantage” said CEO Ellery Buchanan. He went on to say that “FibeRio enables the textiles community to utilize Forcespinning through our rapidly advancing product line of equipment that starts with the Cyclone L-1000 Series and will quickly be joined by roll-roll equipment and scaled up integrated systems.”

The Cyclone L-1000 is designed for the laboratory to enable research and development. With 20,000 RPM, melt temperatures up to 450° and multiple spinneret and orifice sizes to choose from, the full range of Forcespinning Technology can be explored. There is no dielectric requirement, such as in electro spinning, so organic polymers, inorganic polymers, metals and conductive polymers can all be processed.

Business intelligence for the fibre, textiles and apparel industries: technologies, innovations, markets, investments, trade policy, sourcing, strategy...

Find out more