Lord presents lecture on fast curing adhesives

Around 70 academics, students and industrialists from the UK attended an inaugural lecture by Professor Tilak Dias, at Nottingham Trent University’s Newton Lecture Theatre at the end of February. Professor Dias holds the Chair of Knitting in the School of Art & Design at Nottingham Trent University and directs the activities of the School’s Centre for Research in Advanced Textiles (CReATe). Â Within the School of Art & Design, Professor Dias is leading the

25th March 2011

Innovation in Textiles

|

Nottingham

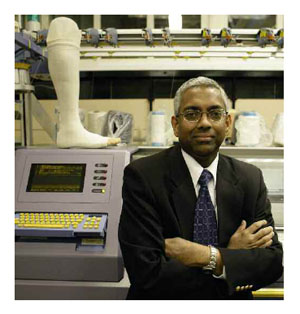

Around 70 academics, students and industrialists from the UK attended an inaugural lecture by Professor Tilak Dias, at Nottingham Trent University’s Newton Lecture Theatre at the end of February. Professor Dias holds the Chair of Knitting in the School of Art & Design at Nottingham Trent University and directs the activities of the School’s Centre for Research in Advanced Textiles (CReATe).

Within the School of Art & Design, Professor Dias is leading the development of research in the fields of knitwear, technical textiles and smart textiles, to enhance the School’s capacity to undertake internationally excellent research.

Setting the backdrop for his inaugural lecture Professor Dias explained:

“When pursuing a fair maiden, who spent far too much time hand knitting, the English clergyman, William Lee, in 1589, invented the world’s first knitting machine. During the next four centuries the technology made quantum leaps progressing into the development of knitting an entire garment seamlessly.”

“This technological revolution has led the application of knitted structures into such diverse fields as varicose ulcer and lymphoedema treatment systems, burns garments, knitted sensors, electrically heatable knitted structures, knee ligament prostheses, eczema garments, and cut resistant clothing for personal protection,” Professor Dias said.

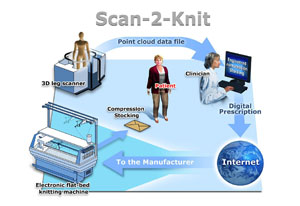

The main aims of the lecture were to introduce a novel technology, named ‘Scan2Knit’, for knitting bespoke compression stockings and the development of electrically active knitted structures by using modern flat-bed knitting machines.

The main aims of the lecture were to introduce a novel technology, named ‘Scan2Knit’, for knitting bespoke compression stockings and the development of electrically active knitted structures by using modern flat-bed knitting machines.

Professor Dias charted the history and development of flat bed knitting technology and explained the three most important factors in knitting: precision control of needles; precision control of knitted loops; and precision control of yarn delivery to needles. Before detailing different positive yarn feed systems he has invented, Professor Dias likened the modern knitwear industry to a ‘craft’ type industry due to its inability or unwillingness to tackle problems related to precision control of yarn delivery.

He then explained the importance of precision yarn delivery systems when developing technologies such as his ’Scan2Knit’ technology for bespoke compression hosiery for lymphoedema treatment. Professor Dias has also taken a similar approach in developing health monitoring knitted sensors, yarns which contain micro-processors and precision textile based heating systems for gloves and garments.

Professor Dias only recently took up the Chair of Knitting in Nottingham and during his academic career at UMIST and the University of Manchester, he founded a multidisciplinary research centre, the William Lee Innovation Centre (WLIC). Here he received financial support from a broad portfolio of funding sources such as EPSRC, NEAT programme, Wellcome Trust, DTI Innovation Funding, ERDF, EU-Equal Programme and UK and US industry, to the total value of £8 million over a period of seven years.

Professor Dias’ research has also resulted in the development of three novel core technology platforms which have resulted in the formation of three spin out companies in the UK for their commercial exploitation. He has published over 95 scientific papers and is named as the lead inventor in 23 distinct patents.

Business intelligence for the fibre, textiles and apparel industries: technologies, innovations, markets, investments, trade policy, sourcing, strategy...

Find out more