Saral StretchSilver 500 ideal for wearables

Fibres become conductive, but fabrics retain breathability and stretch.

9th March 2021

Innovation in Textiles

|

Cambridge, United Kingdom

Combining electronic functionality with textiles allows the sensing of biometric parameters in a comfortable, conformal manner.

While there are many different strategies to make fabrics conductive – such as applying inks printed onto a stretchable substrate – particle-free inks are well suited to directly printing on textiles, says IDTechEx, of Cambridge, UK, which has published detailed studies on this field.

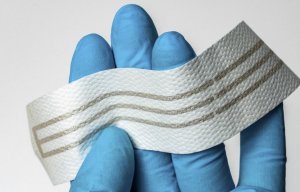

Unlike flake-based stretchable inks, the low viscosity and lack of particles enables particle-free inks to fully permeate textile fibres. Once the ink is metalized by curing, the fibres themselves become conductive, retaining the breathability and stretchability of the original fabric.

Conductive inks are a long-established technology, with silver flake-based inks used extensively in multiple industries, including solar panels and glucose test strips. However, technology rarely stands still, and there is extensive innovation within the conductive ink space. Particle-free inks are an especially promising example with multiple advantages and applications.

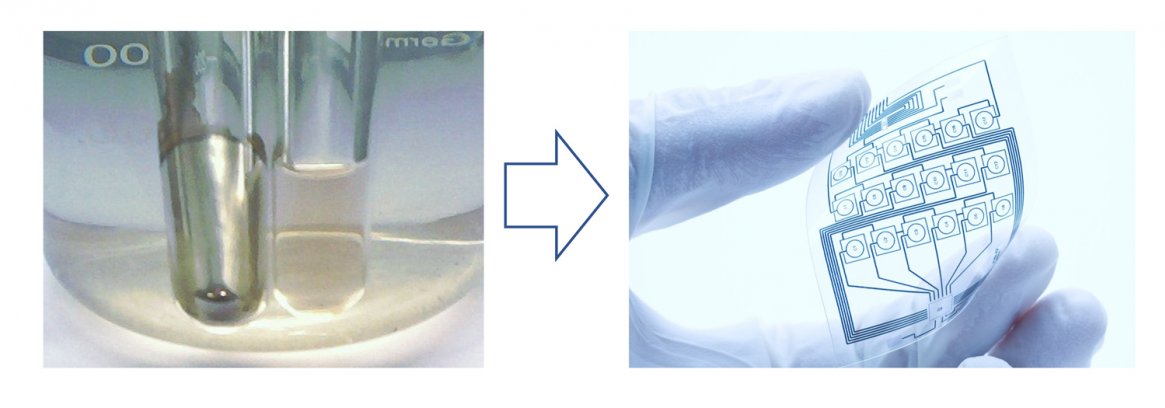

In a particle-free ink, a solvated metal salt is reduced in-situ to produce a metal. In complete contrast to more conventional conductive inks, this means that the uncured particle-free ink is often transparent. The chemical reaction is induced by heat, light or plasma, and produces a smooth conductive metal layer.

High conductivity is a key advantage of particle-free inks. Because the metal is formed in-situ, and the proportion of binder materials can be very low, conductivity can be as high as 80% of the bulk metal. This, of course, means that less ink can be used, with the additional benefit of there being less solvent to evaporate away during curing.

Smooth surfaces

In a classic school chemistry experiment Tollens’ reagent is used to produce a silver mirror on the inside of a test tube uses a reducing agent. This process is similar to that employed with particle-free silver inks. The reflectiveness of the silver coating is due to its smooth surface, which is a key benefit of particle-free inks over their flake-based and even nanoparticle-based alternatives.

In addition to making a reflective surface, smooth conductive traces are highly desirable for radio frequency (RF) applications. This is because as signal frequency increases, surface roughness rather than bulk conductivity increasingly dominates impedance. Furthermore, particle-free conductive inks can be deposited in very thin layers due to their low viscosity. This is advantageous since at higher frequencies, conduction only occurs close to the surface within the ‘skin depth’ of the material, so thinner layers reduce costs as less silver (or other metal) is needed.

Low viscosity

Viscosity, and indeed rheology in general, are crucial in determining the compatibility of conductive inks with each printing method. Since particle-free inks can have very low viscosities and pose no risk of clogging nozzles, they are ideally suited to aerosol and electrohydrodynamic (EHD) printing. Both these emerging techniques have nozzles with very small apertures and are capable of printing at lines as thin as 10 and 1 um, respectively. Depositing lines this narrow enables printed electronics to compete with subtractive methods such as photolithography and thus be used for semiconductor packaging.

Given their attributes, IDTechEx suggests that the following applications are especially well suited to particle-free conductive inks:

-Electromagnetic interference shielding.

-High-resolution printing for advanced semiconductor packaging.

-Printing directly onto fabrics.

In addition, particle-free inks can also be used for applications currently dominated by flake or nanoparticle-based conductive inks.

The reports Conductive Ink Markets 2020-2030: Forecasts, Technologies, Players and Materials for Printed/Flexible Electronics 2021-2031 are available now from IDTechEx.

Business intelligence for the fibre, textiles and apparel industries: technologies, innovations, markets, investments, trade policy, sourcing, strategy...

Find out more