Invisible power from fabrics

By David L. Chandler, MIT New MIT-developed materials are making it possible to produce photovoltaic cells on paper or fabric, nearly as simply as printing a document. The sheet of paper looks like any other document that might have just come spitting out of an office printer, with an array of coloured rectangles printed over much of its surface. But then a researcher picks it up, clips a couple of wires to one end,

14th July 2011

Innovation in Textiles

|

Cambridge, MA

New MIT-developed materials are making it possible to produce photovoltaic cells on paper or fabric, nearly as simply as printing a document.

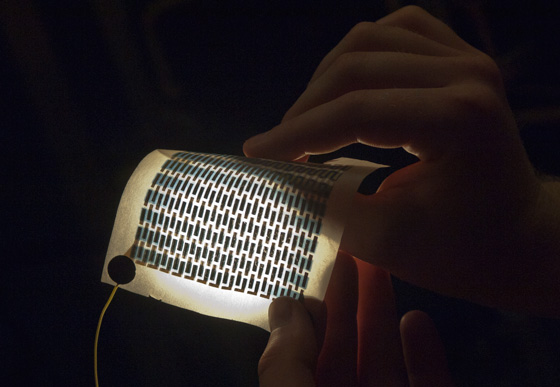

The sheet of paper looks like any other document that might have just come spitting out of an office printer, with an array of coloured rectangles printed over much of its surface. But then a researcher picks it up, clips a couple of wires to one end, and shines a light on the paper. Instantly an LCD clock display at the other end of the wires starts to display the time.

Almost as cheaply and easily as printing a photo on your inkjet, an inexpensive, simple solar cell has been created on that flimsy sheet, formed from special "inks" deposited on the paper. You can even fold it up to slip into a pocket, then unfold it and watch it generating electricity again in the sunlight.

The new technology, developed by a team of researchers at MIT, is reported in a paper in the journal Advanced Materials, published online July 8. The paper is co-authored by Karen Gleason, the Alexander and I. Michael Kasser Professor of Chemical Engineering; Professor of Electrical Engineering Vladimir Bulović; graduate student Miles Barr; and six other students and postdocs. The work was supported by the Eni-MIT Alliance Solar Frontiers Program and the National Science Foundation.

The technique represents a major departure from the systems used until now to create most solar cells, which require exposing the substrates to potentially damaging conditions, either in the form of liquids or high temperatures. The new printing process uses vapors, not liquids, and temperatures less than 120 degrees Celsius. These "gentle" conditions make it possible to use ordinary untreated paper, cloth or plastic as the substrate on which the solar cells can be printed.

It is, to be sure, a bit more complex than just printing out a term paper. In order to create an array of photovoltaic cells on the paper, five layers of material need to be deposited onto the same sheet of paper in successive passes, using a mask (also made of paper) to form the patterns of cells on the surface. And the process has to take place in a vacuum chamber.

The basic process is essentially the same as the one used to make the silvery lining in your bag of potato chips: a vapor-deposition process that can be carried out inexpensively on a vast commercial scale.

The resilient solar cells still function even when folded up into a paper airplane. In their paper, the MIT researchers also describe printing a solar cell on a sheet of PET plastic (a thinner version of the material used for soda bottles) and then folding and unfolding it 1,000 times, with no significant loss of performance. By contrast, a commercially produced solar cell on the same material failed after a single folding.

"We have demonstrated quite thoroughly the robustness of this technology," Bulović says. In addition, because of the low weight of the paper or plastic substrate compared to conventional glass or other materials, "we think we can fabricate scalable solar cells that can reach record-high watts-per-kilogram performance. For solar cells with such properties, a number of technological applications open up," he says. For example, in remote developing-world locations, weight makes a big difference in how many cells could be delivered in a given load.

A paper solar cell circuit is dynamically folded and unfolded while the voltage is simultaneously measured on the meter. The paper photovoltaic is illuminated from below with simulated solar illumination. Video: Advanced Materials/courtesy of the Gleason Lab

Gleason adds, "Often people talk about deposition on a flexible device - but then they don't flex it, to actually demonstrate" that it can survive the stress. In this case, in addition to the folding tests, the MIT team tried other tests of the device's robustness. For example, she says, they took a finished paper solar cell and ran it through a laser printer - printing on top of the photovoltaic surface, subjecting it to the high temperature of the toner-fusing step - and demonstrated that it still worked. Test cells the group produced last year still work, demonstrating their long shelf life.

In today's conventional solar cells, the costs of the inactive components - the substrate (usually glass) that supports the active photovoltaic material, the structures to support that substrate, and the installation costs - are typically greater than the cost of the active films of the cells themselves, sometimes twice as much. Being able to print solar cells directly onto inexpensive, easily available materials such as paper or cloth, and then easily fasten that paper to a wall for support, could ultimately make it possible to drastically reduce the costs of solar installations. For example, paper solar cells could be made into window shades or wallpaper - and paper costs one-thousandth as much as glass for a given area, the researchers say.

For outdoor uses, the researchers demonstrated that the paper could be coated with standard lamination materials, to protect it from the elements.

Others have tried to produce solar cells and other electronic components on paper, but the big stumbling block has been paper's rough, fibrous surface at a microscopic scale. To counter that, past attempts have relied on coating the paper first with some smooth material. But in this research, ordinary, uncoated paper was used - including printer paper, tissue, tracing paper and even newsprint with the printing still on it. All of these worked just fine.

The researchers continue to work on improving the devices. At present, the paper-printed solar cells have an efficiency of about 1 percent, but the team believes this can be increased significantly with further fine-tuning of the materials. But even at the present level, "it's good enough to power a small electric gizmo," Bulović says.

"I am very excited by what is being done" by the MIT team, says Peter Harrop, chairman of IDTechEx, which does research on printed electronics. He says that while most researchers have been focusing on large-scale solar installations that could feed into the electric grid, the potential for other applications "is at least as large. Here the key parameters are very different, with disposable consumer goods, wall coverings and other applications with limited life required."

He adds, "The work at MIT ... is therefore very important. To succeed it must promise low enough cost and low enough sensitivity to humidity." Other attempts to create printable solar cells have been criticized for failing to meet these criteria, he notes.

Source: MIT News

Business intelligence for the fibre, textiles and apparel industries: technologies, innovations, markets, investments, trade policy, sourcing, strategy...

Find out more