Smart materials and wearable technology at Techtextil

Immediate feedback takes over some of the functions of a fitness coach.

16th December 2021

Innovation in Textiles

|

Munich, Germany

A prototype smart exercise machine was introduced at the recent Fitness Connected Expo held in Munich, Germany, by Krefeld-based ZSK Technical Embroidery Systems, a division of ZSK Stickmaschinen GmbH.

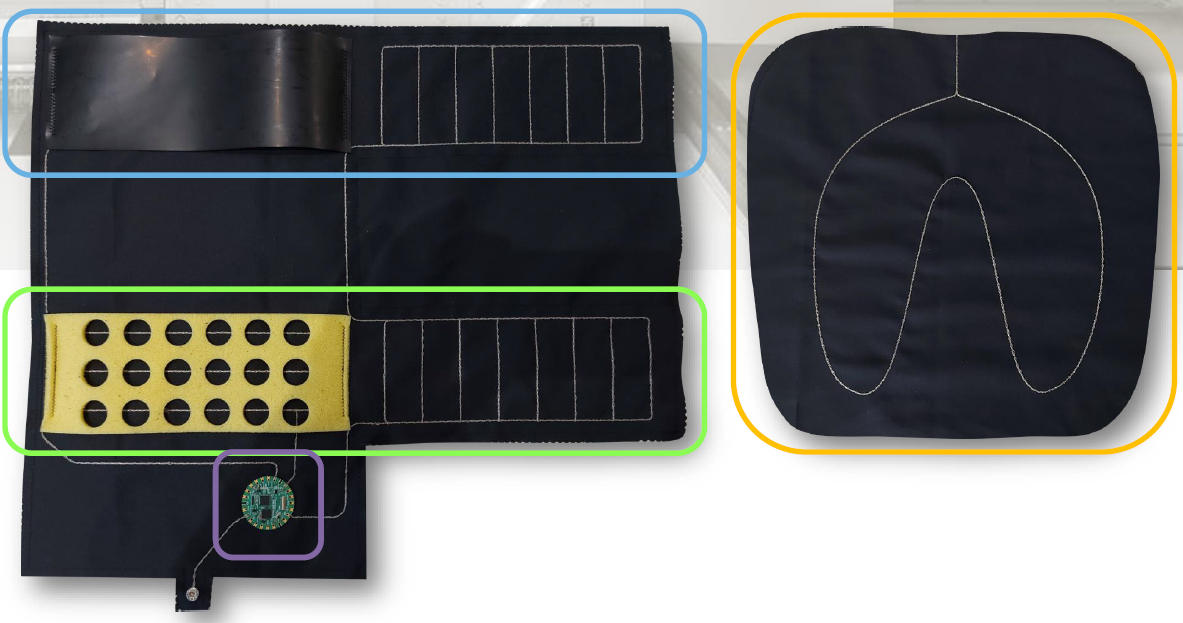

R&D engineer Steliyan Vasilev explained that embroidery with conductive yarns was employed to produce different sensors which were then integrated into the cushions of the machine.

“A capacitive sensor in the seat tells the microcontroller when the machine is occupied, so the remaining sensors and actuators can be activated,” he explained. “A contact sensor in the lower part of the seat’s backrest monitors the correct sitting position of the user and a pressure sensor in the upper part monitors the correctness of the execution of the exercise.”

If the user hyperextends during the exercise or is not correctly positioned, the corresponding vibration motor signals.

The appliqué technique is utilised to realize both the pressure sensor and the contact sensor. For the pressure sensor, piezoresistive foil is applied between two embroidered textile layers. Spacer material with a cut-out hole pattern is used for the contact sensor.

The occupancy sensor is based on capacitive touch sensing technology.

The prototype was developed as a stand-alone device, powered by a conventional power bank which lasted with a single charge for all three days at the exhibition. The data gathered by the integrated sensors was used by the machine itself to provide immediate feedback, taking over some of the functions of a fitness coach. The same data can also be stored on a server or in the cloud for further analysis or linked to a personalized data base.

“Using embroidery allowed us to integrate these sensors directly adjacent to the body without sacrificing any of the qualities of the upholstery, like softness and elasticity,” said Vasilev. “In fact, all three sensors can be embroidered on any ZSK embroidery machine. No specific technical embroidery machine is needed for this application. This makes scaling very easy, as any big ZSK production machine with up to 56 embroidery heads, which is normally used for decorative embroidery, can produce these and many other sensors, leading to significantly reduced production costs.”

Business intelligence for the fibre, textiles and apparel industries: technologies, innovations, markets, investments, trade policy, sourcing, strategy...

Find out more