Hygiene Austria opens online shop to meet mask requirement

Advances in automation continue to make Swedish supplier’s bespoke machines more efficient.

10th February 2023

Innovation in Textiles

|

Ried im Innkreis, Austria

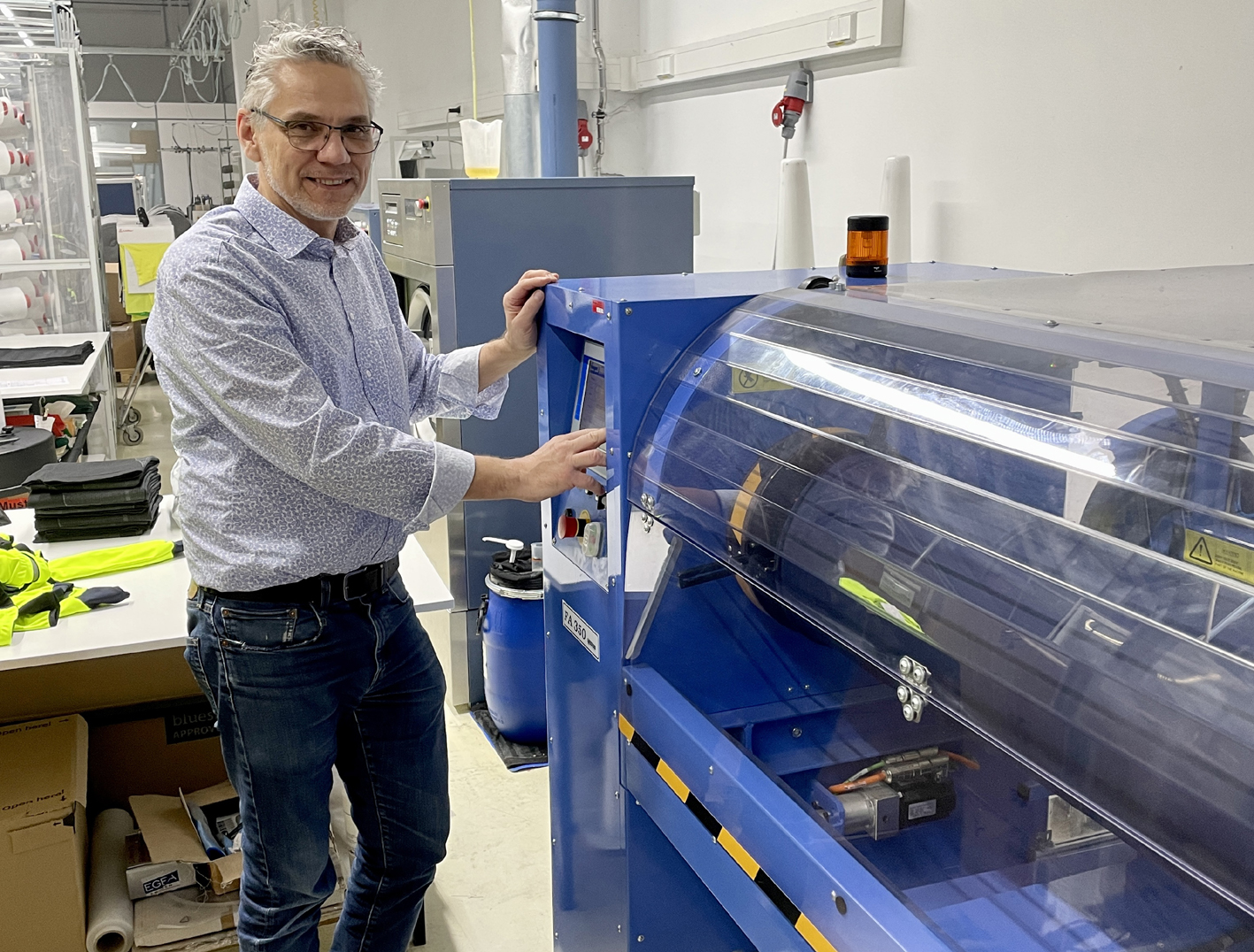

Svegea of Sweden – a member of TMAS, the Swedish Textile Machinery Association – has recently installed an EC300-S collarette cutter for the high speed production of tubular apparel components as well as an FA350 automatic roll slitter at the plant of Löffler, in Ried im Innkreis, Austria.

Anniversary

Sports and knitwear specialist Löffler is celebrating its 50th anniversary in 2023 and its long-held belief in retaining manufacturing in Austria by investing both in its people and the latest advanced technologies at its plant in Ried is now paying dividends.

The plant houses 25 circular knitting machines and three seamless knitting machines with an annual output of around 905,000 square metres of fabric, and in addition to product development, design, cutting and some sewing are all carried out in-house.

“Löffler is part of the family company Fischer Holding, and Ried is the hometown of its owner Josef Fischer, who has been dedicated to maintaining manufacturing here,” says Löffler plant manager Arnold Bowier. “While many competitors have outsourced their production to the Far East in recent decades, we chose a different path. In addition to increasing sales, this strategy has reinforced the cohesion of our employees and also our relationships with key partners.

“Due to steadily increasing sales we have been forced to find local partners within Europe, but our core activities and 70% of all fabrics produced come from the Ried plant. Now we are seeing many competing companies reconsidering where they site their main manufacturing operations.”

Function in every fibre

Löffler is well known for its transtex under garments, which ushered in the two-layer principle of structures combining hydrophobic polypropylene and other fibres like cotton, Modal, Tencel or merino wool.

Before transtex, endurance athletes usually wore pure cotton underwear next to their skin, which became wet over time and cooled the body down. Löffler’s two-layer fabric prevented this, since the polypropylene does not absorb moisture and instead wicks it to the outside, where it can evaporate to keep the skin dry.

Innovation has been ongoing ever since, and in December, Löffler received an ISPO Award 2022 for transtex Retr’x – its latest functional underwear made from recycled polypropylene from textile waste and a combination of recycled and GOTS-certified organic cotton. Transtex Retr’x is neither dyed or bleached and is Standard 100 by Oeko-Tex as well as Made In Green by Oeko-Tex approved.

In addition to its own branded products, the plant makes sports garments for sister company Fischer, which is also based in Ried, and is at the same time involved in significant government tender projects, including the supply of polo shirts for the Austrian Red Cross and for the German and Austrian police forces. Combined, Löffler and Fischer employ approximately 700 people in the region of Upper Austria.

Advanced automation

Bowier and his team built up a strong relationship with Svegea’s technicians during the installation and commissioning of the new machines.

“The machines were delivered directly from Sweden and prepared and adjusted perfectly,” Bowier says. “Because Covid-19 restrictions were still in place during the commissioning phase of the roll slitter, installation training was carried out remotely, with Svegea’s Technical Engineer Erik Bernhardsson guiding us through the process with patience and good humour and providing lots of hints and tips for handling the machine.”

Svegea’s EC 300-S collarette cutter is equipped with the computer-controlled True-Drive II and high pre-feed device and is used by garment manufacturers around the world for the production of tubular apparel components such as cuff and neck tapes and other seam reinforcements. It operates at speeds of up to 20,000 metres per hour. The integrated, fully automatic FA350 roll slitter FA500 roll slitter is equipped with three separately adjustable settings enabling three different band widths to be cut within the same cutting cycle. Automatic tube sewing units are provided for sewn tubes in optional rolled or flat folded forms, depending on customer preference.

“Advances in automation continue to make the specialised, bespoke machines we engineer more efficient,” says Svegea managing director Håkan Steene. “The garment components our collarette cutters produce make it logical for them to be integrated into a company’s making-up operations and at the moment we’re seeing a lot of interest in the reshoring of operations by our customers, to bring final-stage manufacturing closer to the key European or US markets. Löffler, however, has for many years bucked the trend and retained its manufacturing in Austria.”

Business intelligence for the fibre, textiles and apparel industries: technologies, innovations, markets, investments, trade policy, sourcing, strategy...

Find out more