IFAI Expo 2021 opens call for presentations

Opinion

As global trade uncertainties show little sign of abating, textile trade shows are becoming a litmus test for market confidence.

18th December 2018

Marie O'Mahony

|

Dallas, TX

As global trade uncertainties show little sign of abating, textile trade shows are becoming a litmus test for market confidence and nowhere more so than in North America at this present time. The Industrial Fabrics Association International (IFAI) held their annual EXPO2018 at the Kay Bailey Hutchison Convention Centre in Dallas, Texas on 15 – 18th October attracting 4,350 participants. Now in its 98th year, the show covers market segments then include medical, health, protection, safety, Smart fabrics, with applications from military to medical, Sportswear, automotive, Space, construction and engineering.

Jeff Rasmussen, Director of Market Research at IFAI presented an overview of the US market for advanced textiles/product (ATP). With a growth of 8.8% in 2017, Rasmussen predicts a similar growth level for the current year buoyed by consumer confidence driven by a slight lowering in the US unemployment rate. He noted a trend towards a strengthened between the smart textile market and other advanced textile sectors such as protective and performance.

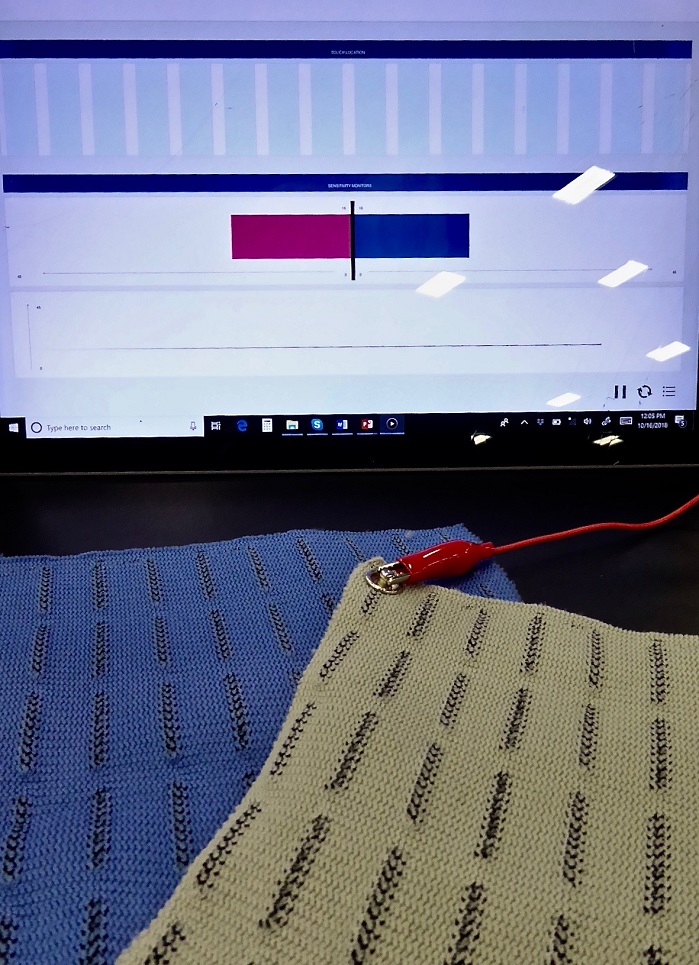

This was borne out by some of the collaborations and cooperation on the show floor such as Volt Smart Yarn’s exhibition both that was shared with Lumenus. The former producing conductive and sensing yarns, the latter smart clothing such as an illuminated jacket for night time joggers and cyclists. The relationship between performance clothing and smart textiles is especially important given the performance clothing market for US ATP was $46.9bn (72% market share) in 2017 compared with smart textiles at just $1.2bn (2% market share).

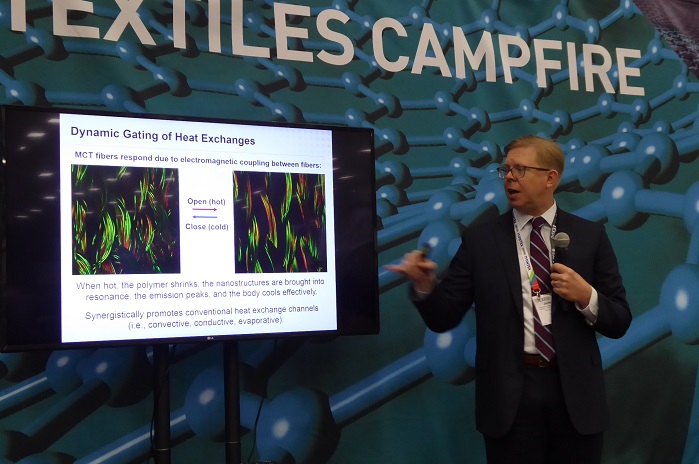

Smart and e-textiles in particular drew a great deal of attention at the expo this year, as it did last year also. Manufacturer booth displays were complemented by a series of formal presentations, panel discussions and informal ‘Fireside Chats’ by individual exhibitors. Rasmussen sees the sector as benefitting from the link with strong (military) and highly visible (sports) markets. This is coupled with access and interest from cutting edge technology industries notably the electronics industry. One of the most interesting things about attending the IFAI show is name badge spotting. Most are from expected areas, but there are occasional surprises made all the more intriguing when people will only agree to talk about why they are there off the record. Last year it was automotive and this year online businesses not currently producing any textile related product. In both instances these people were attending every smart textile event at the show.

“Smart Fabrics in the last two years have made more progress than in the last 15 years” according to Jeff Rasmussen, who went on to describe the opportunities for growth that he sees there while tempering his enthusiasm with a warning that this is still a young market that has yet to establish critical mass with consumers. Laundry remains an issue along with other technical obstacles such as bringing together hard and soft materials in one product in a way that is less labour intensive and more robust.

Standards, national and international were the most eagerly debated topics of the show. The IPC’s Chris Jorgensen provided an update on the IPC-8921 standard development that relates to the Requirements for Woven and Knitted Electronic Textiles (e-textiles) integrated with Conductive Fibers, Conductive Yarns and/or Wires. The industry group are looking to build a classification system and compose a list of functional characteristics that can be tested reliably. Separate standards will be drawn up to address printed, nonwoven and other formats. This will enable a more timely publication of standards for fibers and yarns. The scale of the task can be seen in the list of key performance characteristics where terms and technical language alone can take time to address in a single document such as requirements for material, electrical, surface, mechanical and the environment.

One of the audible ‘aha’ moments came during discussion during Carole Carey of C3-Carey Consultants’ talk on standards for smart textiles in medical applications. While many manufacturers tend to beat a hasty retreat on hearing the words ‘FDA’, there are two different levels that many are unaware of. FDA Approval is the most onerous in terms of time and cost taking 3-5 years to get there. But this applies to Class III that carries the most risk. FDA Clearance on the other hand is faster (90 days was mentioned) and can be used where products are largely the equivalent or substantively similar to one that is already in the market. More detailed descriptions are on the FDA website but here is a brief official FDA description of each:

Cleared medical devices: These medical devices are ones that FDA has determined to be substantially equivalent to (similar) another legally marketed device. A premarket notification submission is referred to as a 510(k) and must be submitted to FDA to review and provide clearance.

Approved medical devices: Approved medical devices are those devices that the FDA has approved a premarket approval (PMA) application or a Humanitarian Device Exemption (HDE) application. This review and approval process is for Class III medical devices (the ones with the highest risk) and involves a more rigorous review than the 510(k) review process.

Industry association trade shows such as this perform an important function in student and future workforce engagement. Strategically, the advanced textile industry in America and elsewhere is struggling to attract and retain a skilled workforce. The IFAI expo includes a student competition each year that focuses on some of the technical and design concerns of industry while highlighting the skills of university and college students and researchers. Students from the University of Minnesota, J. Walter Lee, Stephanie Wang and Caroline Albers, won first prize in the student competition this year for their Intra-spacesuit Electromyography Garment.

The project addressed the issue around the mechanism for addressing astronaut injuries inside rigid spacesuits where access to meaningful data around intra-spacesuit body motions is difficult to access because of visualisation restrictions. The students looked at an alternative method by recording muscle activation signals using electromyography (EMG). Conventional EMG is bulky, needing extensive electrodes and wires with signal noise causing interference with data gathering. To address these challenges for aerospace applications of EMG the students designed an upper-body garment to collect the EMG data on muscle activity inside spacesuits. Constructed with form-fitting textiles combined with pattern-cutting that considers both the core functionality and data gathering functions, the researchers see the garment as providing a viable non-invasive EMG study solution that maximizes applicability without impeding the wearer’s mobility or comfort.

In a digital age where data can be exchanged, connections made and orders places online the trade show is becoming even more focused on people and personal connections. This makes education events an important draw for visitors, not just for the presentations themselves but for the opportunity to make new connections amongst likeminded people across a range of industries. For the IFAI, the relaxed approach to hosting many of the events on the showroom floor where visitors can literally drop in on between booth visits were often better attended than more formal sessions in traditional conference room environments. Under the new presidency and CEO of Steve Schiffman the show will undoubtedly see some changes in the next few years. But the American advanced textile industry has never been about seismic shifts, so that anything new at EXPO2019 will likely be evolutionary rather than revolutionary. In the current trade climate many will view that with some relief.

Business intelligence for the fibre, textiles and apparel industries: technologies, innovations, markets, investments, trade policy, sourcing, strategy...

Find out more