Freudenberg introduces Eco-Check product label

Label indicates products offers significant direct advantages in terms of environmental protection.

6th July 2022

Innovation in Textiles

|

Weinheim, Germany

Freudenberg Performance Materials is endorsing five further sustainable products with its Eco-Check label, introduced last year.

“The Eco-Check label is a quick and easy way for our customers to identify particularly sustainable solutions,” said CTO John McNabb. “The company’s sustainability label is only used to endorse products that either save resources during production, improve the manufacturing footprint of customers, can be disposed of in an environmentally friendly manner after use, or contain certain features that contribute to a long service life. The label indicates to our customers that a product offers significant direct advantages in terms of environmental protection, leading to more sustainable solutions.”

New Eco-Check products include an Evolon microfilament reinforcement material for leather goods that is manufactured with no solvent or binder. It contains up to 80% recycled PET and is suitable for a broad range of applications. The material is produced at Freudenberg’s facility in Colmar, France, where the manufacturing process is highly sustainable. It is certified to STeP by Oeko-Tex and fully complies with the Detox to Zero by Oeko-Tex criteria.

In the field of healthcare, the bio-based M 1714 wound pad with superior absorption for more challenging wounds has now also been endorsed with the Eco-Check label. The dressing consists of a mix of bio-based fibres derived from natural sources and exhibits a smooth wound contact layer. The product has been evaluated for industrial compostability and conforms to ISO 13432.

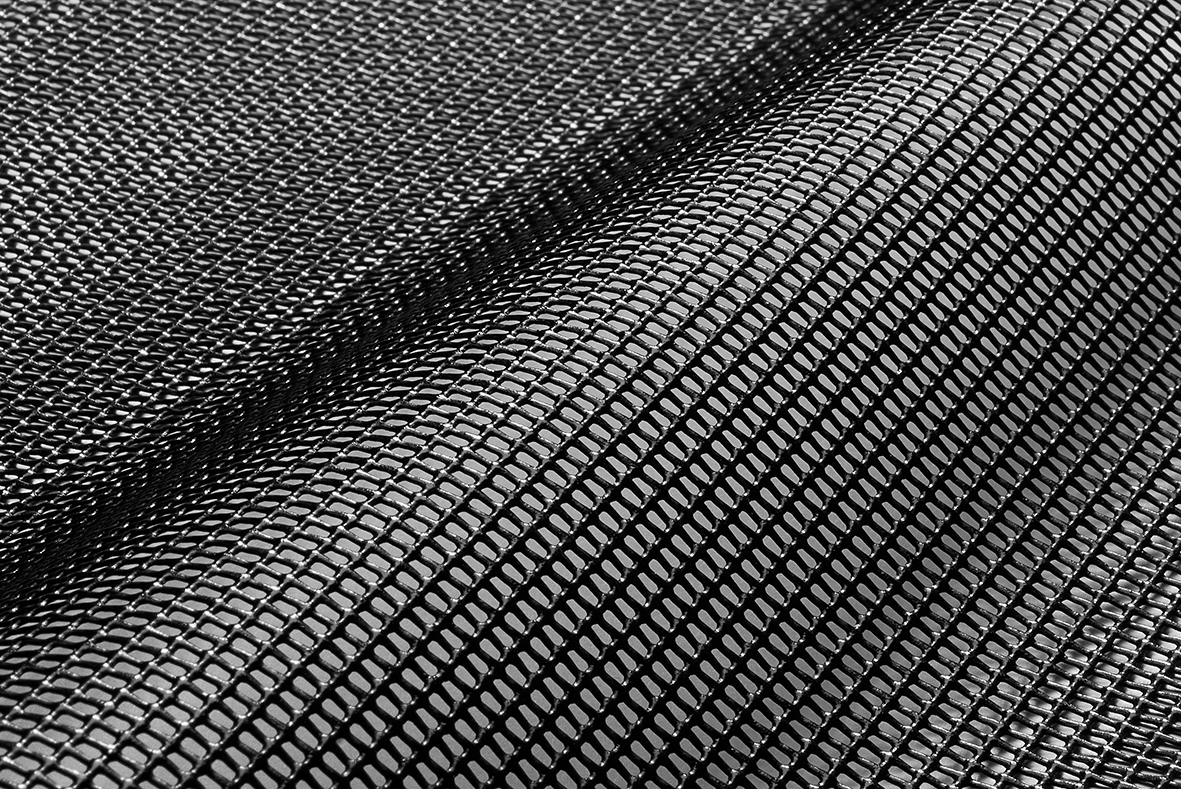

Another labelled product is TF 400 Eco F mesh fabric for textile architecture from Mehler Texnologies. Its yarn is made of 100% recycled PET bottles and its characteristics are very similar to those of conventional mesh fabrics. In 2021, it received an award from the Architectural Membrane Association in recognition of its properties.

In the shoe industry, the binder-free strobel insoles have been endorsed as particularly sustainable. They contain a high percentage of recycled green bottle flakes and the insoles themselves are fully recyclable. A two layered, needlepunched nonwoven filter media now endorsed with the Eco-Check label is made entirely of polyester and more than half the fibres consist of recycled material.

Freudenberg Performance Materials pioneered PET recycling in the early 1990s and today uses an estimated seven million PET bottles annually in its own manufacturing processes. The materials produced consist of 100% recycled PET and are of the same quality as conventional products.

Business intelligence for the fibre, textiles and apparel industries: technologies, innovations, markets, investments, trade policy, sourcing, strategy...

Find out more