Indorama commits to science-based targets

Defence technology designed in Israel can turn the fashion industry’s linear “take-make-dispose” economy around into a sustainable one.

30th September 2019

Innovation in Textiles

|

Melbourne

The fashion industry produces around 100 billion garments per year. © Nick de Partee on Unsplash

Security Matters (SMX), an Australian-listed Israeli tech solutions company with clients in the electronics, minerals, plastics, security, and agriculture industries, has a solution used in security and defence that it believes can help reduce the volume of garments and textiles that are incinerated or landfilled every year.

The global EUR 1 trillion-a-year fashion industry is facing increasing consumer and political pressure to reduce its oversized environmental impact. Currently, less than 1% of textiles produced for clothing is recycled into new clothes, representing a lost opportunity of more than US$ 100 billion annually and high costs for landfilling and incineration: 87% of material used for clothing production is landfilled or incinerated.

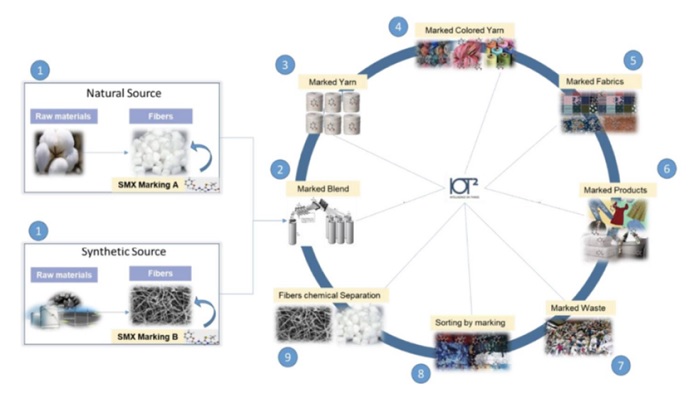

The greatest hurdle in turning fashion’s high-resource and high-waste linear economy to a circular one is sorting materials so they can be recycled, enabling the re-use of raw resources. SMX’s proprietary Intelligence on Things (IOT2) technology marks the molecular matter of raw materials before they are made into textiles and then garments, and embeds deeper than bar codes, QR codes or RFID chips, which are attached only on product packaging. This molecular marking aims to tackle fashion industry’s biggest hurdle of sustainable recycling and reuse.

The marking system is embedded in all three life cycles and the numerous, multi-layered data is secured stored on blockchain. © Security Matters

“Being able to sort out threads – whether they are cotton, linen, polyester or blends – will enable a new equilibrium for a circular economy to thrive: as fibre made into fabric, then fashioned into clothes, can re-enter the economy for reuse and recycling; rather than ending up as waste once they are no longer wanted,” said Haggai Alon, SMX’s CEO and co-founder.

After the oil industry, the fashion industry is the second biggest pollutant. It produces around 100 billion garments per year, and is responsible for 8-10% of the world’s greenhouse gas emissions (more than those of all international flights and maritime shipping combined); contributing to about 20% of industrial water pollution in the world; consuming some 98 million tonnes of oil; producing some 92 million tons of solid waste each year; and releasing 22 million tonnes of plastic microfibres into the ocean from 2015 to 2050 based on current trends.

According the UN Alliance for Sustainable Fashion, US$ 500 billion of value is lost every year due to clothing underutilisation and lack of recycling. This is in large part due to the lack of correct labelling and material identification, which are paramount to accurate sorting of collected goods for recycling.

As textiles tend to be made from a blend of cotton, polyester and other materials, the recycling process is easier and most efficient when treating one type of material, such as polyester – plastic-based fibres that represent 60% of clothing textiles. Efficient recycling technologies rely on accurate material detection and sorting to ensure well-defined material streams.

SMX’s technology can invisibly mark raw fibres at a molecular level from the original source across three life cycles: raw material to production, production to commercial, and commercial to recycling and re-use, the company explains.

The marking system is embedded in all three life cycles and the numerous, multi-layered data is secured stored on blockchain. When SMX-marked garments are collected at a recycling centre, the raw materials can be accurately identified by SMX’s scanner to enable sorting and extraction of high-quality recycled fibres. Pure materials can be recaptured, allowing brand owners to recycle them, resulting in saved money and energy.

SMX’s food-grade, non-radioactive technology was originally developed by Soreq Nuclear Research Centre, an Israeli government R&D institute for nuclear and photonic technologies under the Israeli Atomic Energy Commission and used for security purposes by the Israel Defence Force.

“SMX’s mark and trace technology enables an ‘equilibrium economy’ as it covers data across three life cycles and logs the information on blockchain for authentication and proof. We’re tackling a problem that can only be solved now because of our technology and ability to mark different materials (e.g. textile fibres, rubber, plastic, metals, gold, diamonds, etc) at source and detect them in the finished product for greater recycling output quality,” said Mr Alon.

“With SMX’s equilibrium economy, fashion brand owners can also look at a new business stream, with credible carbon credit claim.”

Business intelligence for the fibre, textiles and apparel industries: technologies, innovations, markets, investments, trade policy, sourcing, strategy...

Find out more