Material efficiency and recycling in manmade fibres

Automated precision dismantling the key to high quality and high volume recovered materials.

9th July 2025

Innovation in Textiles

|

Japan

The BlueRebirth Council is a new consortium of Japanese companies which is aiming to establish an integrated manufacturing and recycling value chain to realise the robotic material recovery and recycling, including textile components, from used vehicles.

The global automotive textiles market encompasses far more than just visible upholstery and flooring fabrics. Nonwoven fabrics are employed widely in filtration, insulation and padding, while fibre reinforcements are at the core of an increasingly wide number of composite parts.

While all of these materials are eminently recyclable and fabric suppliers are developing monomaterial components and basing materials on recycled fibres, the infrastructure for materials recovery is simply not yet in place.

Shredding and sorting

The most common method of dealing with end-of-life vehicles (ELVs) is by shredding, followed by material sorting, which makes it extremely difficult to secure high purity recycled materials.

In addition, collaboration between the manufacturing and recycling industries has not been sufficient and as a result, initiatives to use recycled materials as automotive components – which require both high quality standards and adequate supply volumes for mass production – have not progressed.

The automotive recycling industry also faces challenges in promoting automation and digitalisation and in addressing worker shortages by improving workplace environments.

In the USA, for example, metals, tyres and glass currently account for 80-90% of the materials from end-of-life vehicles that are currently recycled through traditional mechanical recycling streams.

The other 10-20% is rather tragically referred to as ‘automotive shredder residue’ (ASR) and consists of most of the valuable textiles, mixed plastic and other non-recycled materials that today generally end up in landfills or are recovered through waste-to-energy technologies.

Value chain

This is a situation the BlueRebirth Council, which brings together the companies Denso Corporation, Honda, Matec, Nomura, Rever Corporation and Toray Industries, has been formed to change.

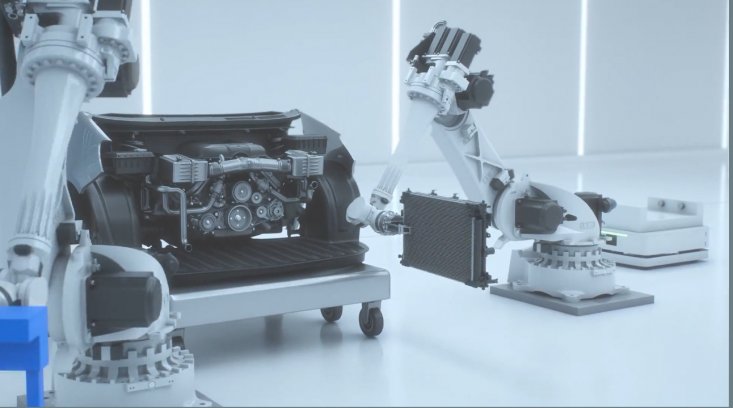

It aims to build a manufacturing and recycling integrated value chain to realise car-to-car recycling, starting with automated precision dismantling to efficiently disassemble end-of-life vehicles (ELVs) for material recovery and recycling.

BlueRebirth will work to advance technology development and demonstration projects together with participating companies, research institutions and other stakeholders, starting with the automated precision dismantling of ELVs to build a manufacturing and recycling integrated value chain.

Automated precision dismantling utilises AI and sensor technologies to enable robots to operate along the optimal path, even for deformed parts. This, the council believes, will not only ensure the quality and volume of recycled materials that are difficult to achieve with conventional methods, but also contribute to making the working environment more attractive.

Business intelligence for the fibre, textiles and apparel industries: technologies, innovations, markets, investments, trade policy, sourcing, strategy...

Find out more