Airtech introduces new LTC3 carbon prepregs

Aiming for a capacity of 5,000 tons of recycled material annually at the first production site.

29th November 2021

Innovation in Textiles

|

France

Hexcel Corporation and Fairmat, a deep technology startup based in France, plan to establish the capability to recycle carbon fibre prepregs from Hexcel’s European operations for reuse in composite panels sold into commercial markets. It is intended that as a result, most of the carbon fibre prepreg cutoffs generated at Hexcel plants in Europe will be repurposed by the end of 2022.

“With Fairmat, Hexcel has found an industrial recycling solution for the carbon fibre prepreg cutoffs generated at our European facilities,” said Thierry Merlot, European president of aerospace at Hexcel. “This partnership represents a significant step as we continue striving to be an industry leader and a responsible steward of resources. From lightweight composites that help reduce emissions to improving our processes to reduce our impact on the environment, Hexcel is relentless in our pursuit of innovations that will lead to a more sustainable future. So, we are delighted with this key collaboration.”

Under the partnership, Fairmat will lease a former Hexcel facility in Bouguenais (Loire-Atlantique) where it will recycle cutoffs generated during carbon fibre prepreg production at Hexcel’s European plants. Fairmat will begin to set up the new site in early 2022 with production scheduled to start in March 2022.

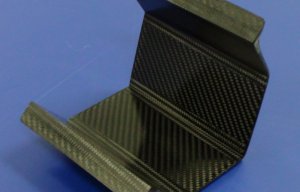

Fairmat has developed a virtuous recycling process capable of circularising the manufacture of carbon fibre composite materials, giving a second life to this high value-added material. Carbon fibre and resins are mainly cold treated, leading to reduced energy costs and avoiding traditional landfill or incineration solutions. Fairmat’s clean recycling process is expected to save 41 kg of CO2 emissions per kilogram of recycled carbon fibre composite compared to virgin prepregs. Fairmat is aiming for a capacity of 5,000 tons of recycled material annually at this first production site.

“We are proud of the trust Hexcel has placed in us by signing this strategic partnership,” said Fairmat founding chairman Benjamin Saada. “The commercial agreement covering the first tons to be recycled in Europe will enable us to complete the industrial scale-up of our recycling technology by the end of the year. I originally founded Fairmat with a totally circular vision in mind, so it was important for me to be able to reuse an existing industrial facility to launch our production. I’m delighted that Fairmat is rapidly advancing toward its goal of giving advanced materials a second life.”

Business intelligence for the fibre, textiles and apparel industries: technologies, innovations, markets, investments, trade policy, sourcing, strategy...

Find out more