Huafon Microfiber to install four more lines from DiloGroup

The emphasis will be on new equipment components which aim improve product quality and increase line capacity.

19th February 2016

Innovation in Textiles

|

Eberbach

Dilo, the leading equipment supplier of complete lines for staple fibre nonwoven fabric production, will be promoting the most recent machine concepts from DiloGroup companies DiloTemafa, DiloSpinnbau and DiloMachines at the IDEA 2016 exhibition that takes place from 3-5 May 2016 in Boston, US.

The company will be exhibiting its latest technology with the emphasis on new equipment components which aim improve product quality and increase line capacity.

DiloTemafa has introduced versions of the Baltromix bale opener and the card willow, which are particularly suited to the processing of longer fibres at highest throughput. Longer cleaning intervals and shorter cleaning times also result from the design changes, according to the manufacturer. The DON dosing opener remains as an intermediate between fibre preparation and the card feeder and provides a fine opening stage.

DiloSpinnbau has a new Unifeed card feeder, which combines the principle of volumetric charged feeding with the characteristics of a chute feeder but without the conventional overhead trunk which allows for lower ceiling height requirement. The fibre flock matt is condensed by a vacuum delivery apron to give better uniformity of mass distribution. Additional flaps control this over the working width. This feeder can be adapted for medium/fine to coarse and medium to long staple fibres.

The newly developed card VectorQuadroCard incorporates a modular transfer group between breast and main section. The quick change facility of this roller group provides different carding options. The delivery system is also flexible to provide parallel laid, random or condensed web.

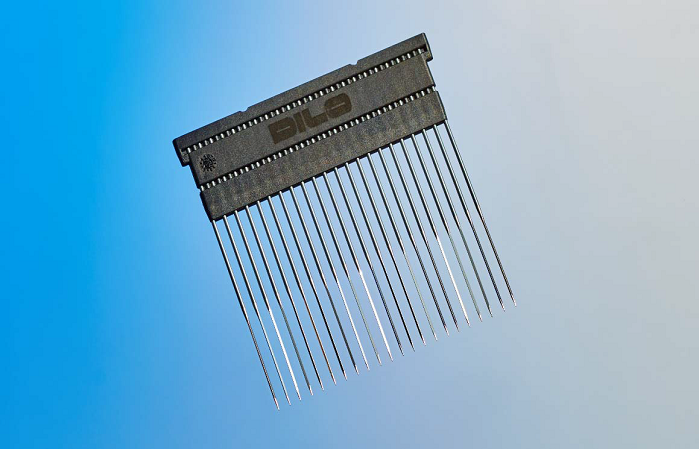

Developments underway relating to the needling process include needle module technology, whereby needles are pre-mounted in multiple units of 22 for insertion into very high density boards. Needle insertion and precision will be increased particularly with the possible use of robot technology, the company reports.

According to the manufacturer, Variopunch needling technology could employ these multi-needle modules to erase bad spots in a felt by a variable needle arrangement in order to achieve a better evenness of the stitching pattern. When fully developed Variopunch is intended to allow a more homogeneous distribution of stitches for superior surface quality.

In addition to wide needling lines for the economic production of large volume products as in the geotextile industry, Dilo offers a compact line which is designed for the production of small amounts of high quality felts, used in applications, such as the medical sector and for specialty felts made from specialty fibres.

This compact line includes fibre opening and blending, card feeding, carding and crosslapping, needling and winding. The working width of the compact carding machine is 1.1 m, the layering width is 2.2 m.

The line which was first presented at the ITMA 2015 in Milan, Italy, is characterized by consistent focus on a compact line layout, a fast adaption to changing production conditions and an economic mode of operation, the company reports.

For this purpose, numerous innovations were realized in every single machine. These innovations are also said to facilitate the modifications necessary for the needling of carbon fibre.

Business intelligence for the fibre, textiles and apparel industries: technologies, innovations, markets, investments, trade policy, sourcing, strategy...

Find out more