Groz-Beckert at IDEA 2022

Groz-Beckert is presenting its latest innovation: dur.

17th May 2018

Innovation in Textiles

|

Albstadt/Atlanta, GA

Groz-Beckert, a leading provider of industrial machine needles, precision parts and fine tools, will present its product ranges for sewing, felting and carding at the upcoming Texprocess Americas and Techtextil North America trade fairs, which take place from 22-24 May in Atlanta, GA.

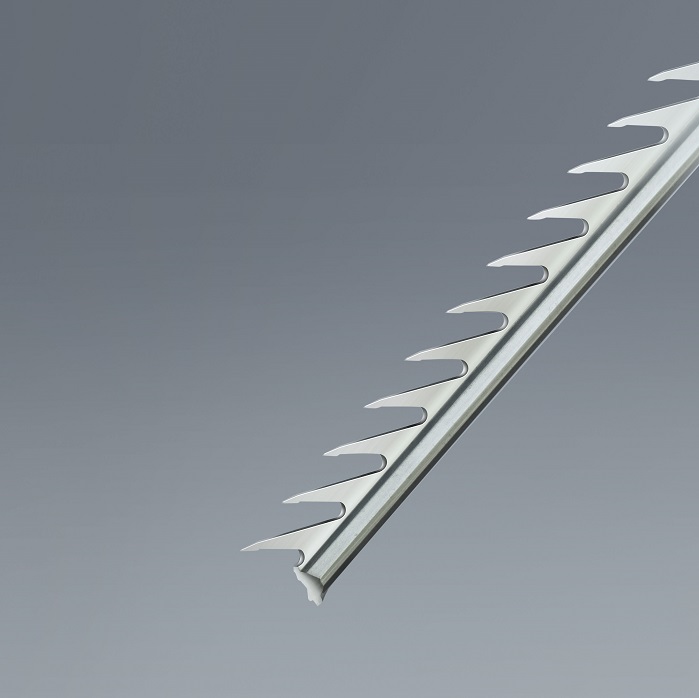

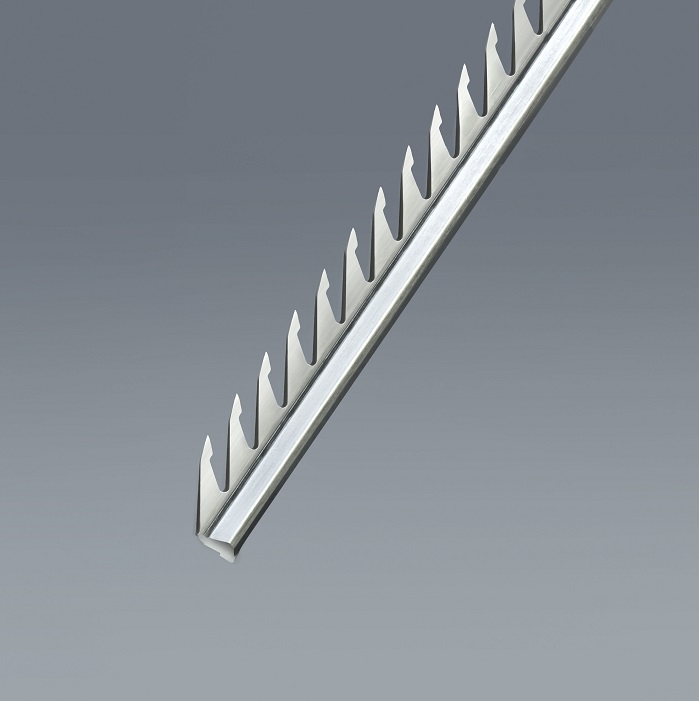

The felting product sector is focused on special needle solutions for different applications in the nonwovens industry. Because the individual needle types from the Groz-Beckert product range vary with regard to barb size and shape, as well as working part gauge and cross-section, the suitable felting needle can be offered for different applications.

Groz-Beckert is presenting its latest innovation: dur. A patented manufacturing process in combination with a new base material are the foundation for an increase in service life of up to 30% and improved corrosion resistance, according to the company.

Groz-Beckert's newest product sector, carding, focuses on the aspects of increased performance and raw material savings: The high-performance worker and doffer wires SiroLock and EvoStep will be on show. Thanks to an improved fibre control, EvoStep card clothings are said to distribute the fibres more uniformly in the web and effectively help to achieve the nonwoven properties. This reduces the raw material consumption to a minimum.

The improved fibre control is also said to enable lower-cost raw materials to be used, which could not be processed with conventional card clothings. SiroLock also offers options for saving on raw material – mainly through the more uniform web quality. The main advantage, however, is the increased performance made possible through higher delivery speeds and web weights. The fibre-friendly surface of the card clothing opens up a wide range of application options with all fibres and fibre blends for different web weights.

A unique exhibit with 3D models will bring the special card clothing series to life for visitors to the Groz-Beckert booth.

In the field of sewing, Groz-Beckert will be focusing on Smart INH. Since 2016, the company has been offering the INH Quality Management (Ideal Needle Handling), a patented process for problem-free and time-saving handling of broken and damaged sewing machine needles. With Smart INH, the latest component of the Quality Management, Groz-Beckert is now enabling the digital documentation of all needle breakages and all other needle changes.

The INH@site app and the administration program INH@office were also specially developed for this: While INH@site can be used to photograph broken needles and document them as a digital image data set, INH@office offers the option of completing these data sets, managing them and running various assessments. This removes the need for physical documentation and storage of the broken needles - paving the way for immediate and environmentally friendly disposal.

A further service highlight in the field of sewing is the customer portal with integrated online shop.

Business intelligence for the fibre, textiles and apparel industries: technologies, innovations, markets, investments, trade policy, sourcing, strategy...

Find out more