Mahlo offers innovative solutions to Russian manufacturers

Mahlo has delivered around 800 units of its universal Mahlo machine generation 15, which was presented to a broad public at ITMA 2015.

12th March 2018

Innovation in Textiles

|

Saal/Donau

Mahlo, a leading German machine builder and an inventor of automatic straightening, has delivered around 800 units of its universal Mahlo machine generation 15, which was developed and presented to a broad public for the first time at ITMA in Milan in 2015.

“In most applications, distorted products are one of the biggest problems to be solved for textile finishers. Distortions change the original structure of the product, reduce the quality and thus the prices to be achieved, and must be eliminated in order to preserve the present utilisation value of the product. Regardless of surface effects, this must be done fully automatically at today's commonly high product speeds,” the company explains.

“Since the introduction of the first automatic weft straightening system in 1959, Mahlo has been intensively involved in this subject and has become synonymous with fully automatic weft thread straightening.”

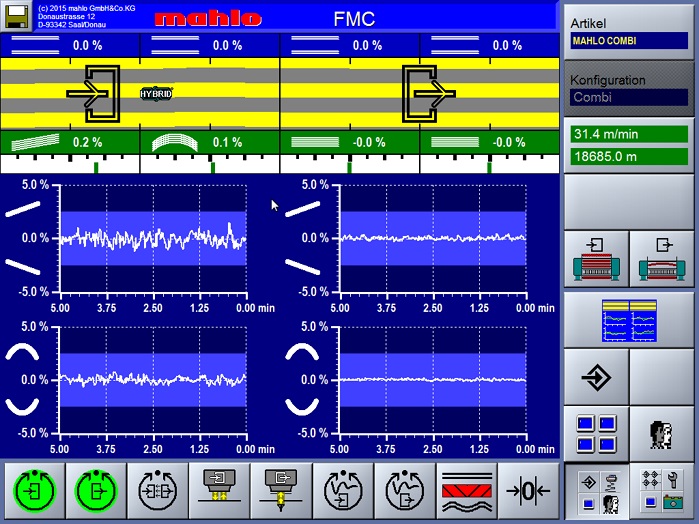

For distortion detection Mahlo utilises sensors with oscillating lens or high-resolution camera. Often these sensors are combined to a so-called hybrid system and the respective advantages of both systems are combined. A self-optimising light source in robust design (IR LEDs) is also always on board and can be used in both transmitted and reflected light operation. A modular system is thus available, which allows Mahlo to provide the right scanning system for almost any application.

“Optoelectronic scanning with oscillating lens and DSP (digital signal processor) is probably the most sensitive and versatile system on the market,” the company reports. Arranged on a carrier bridge, several of these sensors simultaneously detect the position of the weft thread at different points. The scanning system detects and analyses the regular basic structure of the weft threads, courses or rows of tufting. It automatically adapts the control system to a wide variety of textiles, even with the most complicated fabric structures.

The modular design of the system allows for a custom-tailored machine. The further developed software – available as full or basic version – displays all relevant parameters on a freely configurable touchscreen. The user alone decides where exactly on the 12-inch touchscreen the information is retrieved.

In order to correct the measured distortions, the textile user requires a universally applicable straightener. The new device generation 15 has been developed especially for the requirements of the market and has been optimised for almost all applications.

In order to meet the requirements even better, the hardware of the Orthopac RVMC has been revised. Its particular strength is the extremely high straightening accuracy and progressive straightening speed, according to the manufacturer. The highly compact mechanical straightener is equipped as standard with 3 skew and 2 bow rollers. The stepless positioning drive of the straightening rollers with the unique hydraulic unit or frequency-controlled electric motors combines the shortest positioning times with the highest precision and least amount of maintenance. The revised hydraulics work completely without the wear part pressure accumulator and stands out through maximum efficiency with minimum heat generation in the system.

Sensitive product tension control with differential gear and dancer control keeps product tension as low as possible, but still as high as necessary for straightening. A comfortable, innovative configuration tool enables fast integration and synchronisation with the production system.

Mahlo always incorporates the latest developments and market requirements into its developments. The new freely configurable HMI with flat interfaces makes the new generation of devices fit for future requirements, the company says.

“The buzzword Industry 4.0, the vision of interconnected and interacting machines, is currently on everyone's lips. In order to enable the interaction of machines, data must be exchanged reliably and easily configurable via secure communication. The new generation of Mahlo straighteners, sensors and control loops is just a mouse click away from the individual data of existing machines,” the manufacturer explains.

“If a customer uses suitable sensor technology and the appropriate networking, they can access the machine not only from everywhere, provided they have an Internet connection. They also have the option of connecting any machine to the network via an OPC UA server – i.e. an interface for software from different manufacturers – with the fitting connectivity.”

Business intelligence for the fibre, textiles and apparel industries: technologies, innovations, markets, investments, trade policy, sourcing, strategy...

Find out more