Loepfe focus on India

The digital control unit has various innovative features, which are designed to ensure top quality output in the weaving mill.

10th April 2018

Innovation in Textiles

|

Wetzikon

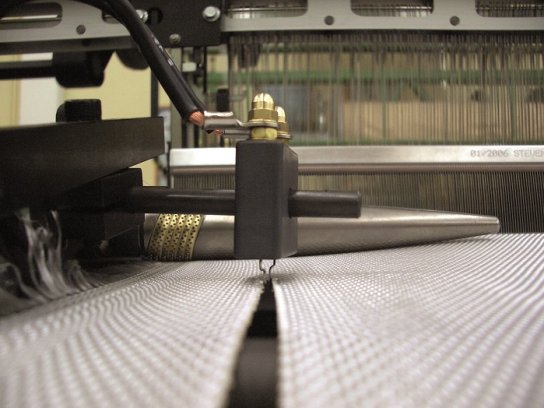

Loepfe, a manufacturer of the WeftMaster TC-1S fabric cutter system, comprising of the hot wire cutter and a matching control unit, is introducing a new digital thermal cutting control unit WeftMaster CUT-iT to ensure constant high-quality selvedges.

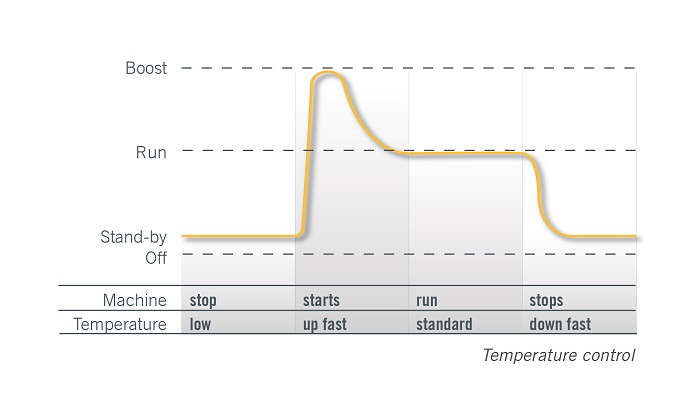

The digital control unit has various innovative features, which are designed to ensure top quality output in the weaving mill. Because of the intelligent control, the cutting temperature remains constant during operation. One control unit can operate up to four hot wire cutters at highest power. The boost mode ensures to reach the temperature needed in a minimum of time during fast machine start-ups, according to the manufacturer.

At machine stops, the control unit reduces the temperature immediately to stand-by. “Thanks to the exact temperature control, the WeftMaster CUT-iT is a perfect match for cutting sensitive and finest fabrics, which are used in filter materials or medical products,” the company explains.

The newly designed user interface makes the temperature settings very easy. Up to ten user-defined settings can be added to the predefined settings. This ensures reproducible high quality for frequent lot-changes, as the temperature setting is recalled with a press of a button.

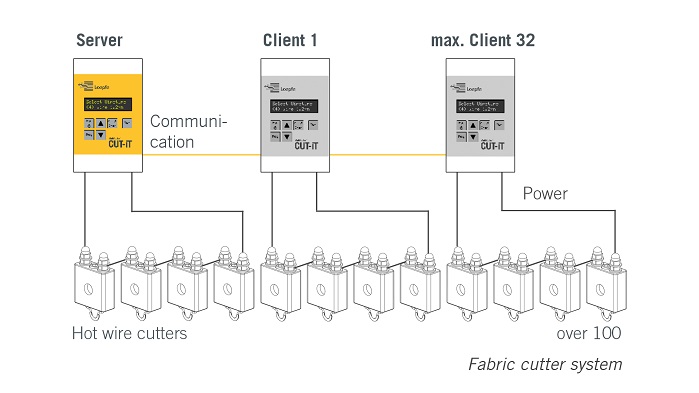

“The feature of storing lot settings results in the direct benefit of reproducible quality and the easy and timesaving processing of new orders,” said Luc Vanoverschelde, Product Manager at Loepfe. The WeftMaster CUT-iT control unit can operate in Client-Server mode with a maximum of 32 client units. When changing the setting on the server unit, the settings on all client units change simultaneously.

This new functionality allows operating over 100 cutters in parallel. A typical application is the production of ribbons out of woven fabrics. The new thermal cutting control unit operates with 24 V DC. The power comes from the weaving machine or an industry standard power supply is used.

“Loepfe´s WeftMaster CUT-iT is the ideal fabric cutter system for thermal cutting from thin and light to dense and heavy synthetic fabrics. All applications with a high-quality demand benefit from the innovative solution. Typical applications include carpet backings, airbags, geotextiles, and labels for clothing,” the company concludes.

Business intelligence for the fibre, textiles and apparel industries: technologies, innovations, markets, investments, trade policy, sourcing, strategy...

Find out more