Largest-ever order for Oerlikon Neumag

André Wissenberg explains the role of sustainable production and aspects under which Oerlikon develops future-oriented products and applications.

7th May 2015

Innovation in Textiles

|

Remscheid/Frankfurt

With the Oerlikon Barmag and Oerlikon Neumag brands, the Oerlikon Manmade Fibers Segment is a market leader in the field of filament spinning machines for manmade fibres, texturing machines, and BCF, staple fibre spinning and nonwoven systems, with a special focus on sustainability.

André Wissenberg, Vice President Marketing, Corporate Communications and Public Affairs, describes the multitude of aspects under which the Oerlikon Manmade Fibers Segment develops future-oriented products and applications.

“Sustainability has always played an important role in the Oerlikon Manmade Fibers Segment,” he explained. “This is why we launched, among other things, our e-save programme in 2004, which we have consistently expanded through other Health, Safety and Environment initiatives over the years.”

“Sustainability relates to three areas: economy, environment, society. We are constantly making improvements for our customers and in particular for our employees in all three of these areas. In production, for example, in recent years we have improved processes where appropriate in all production facilities as part of the company-wide Oerlikon Operational Excellence programme,” said André Wissenberg.

“In Remscheid, the newly developed One-Piece Flow Concept has been implemented for the new WINGS POY 1800 production line and for the production of the traverse beams. This has not only allowed us to increase production capacity by 15%, it has also brought ergonomic benefits for the assembly workers. And it has been possible to reduce energy consumption.”

“We then use such experience at our other German sites, and international sites in China, India and the USA. We are also very active as far as health and safety is concerned. Our employees are able to benefit from age-appropriate workstation optimisation and the redesign of break rooms, to the food on offer in the canteen.”

“The entire Oerlikon Group is constantly investing in innovations to strengthen its leading technological position. Compared to the previous year, expenditure on Research and Development in 2014 rose by 19.8% to CHF 121 million, which is around 4% of turnover. In concrete terms, last year's R&D activities resulted in applications for 108 new patents,” explained Mr Wissenberg.

“We always provide our customers with cutting edge technology. With an annual R&D spend of around CHF 30 million, more than 200 engineers and almost 1,200 patents, we have been building on our leading innovative position in the manmade fibre industry for decades.”

“With the constant expansion of our e-save philosophy we are pursuing constant value creation and enhancement for the manmade fibre industry with high-grade, innovative solutions. We are renowned world-wide for being the experts in our industry. This is thanks to our more than 90 years of experience in all areas of manmade fibre production technology.”

“Today, all innovations are developed by us under the four e-save aspects of energy, economics, environment and ergonomics. The products and technologies developed by us enable our customers to secure sustainable success in the market,” said Mr Wissenberg.

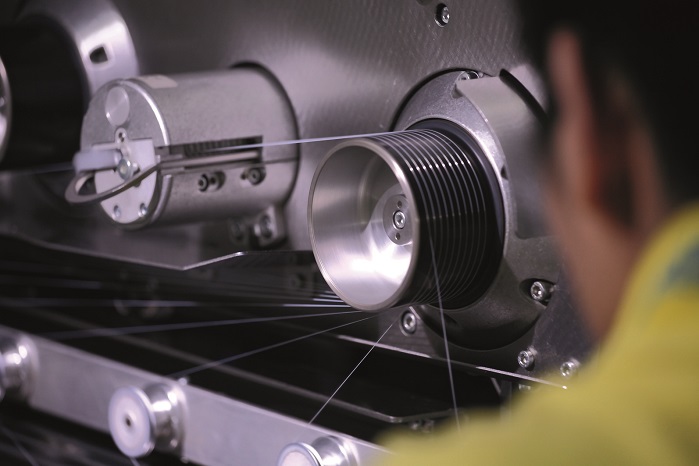

“Or product solutions for the spinning of manmade fibres, in particular, make a significant contribution to sustainable and economic production. I can give you two examples: Our latest WINGS technology (Winder Integrated Godet Solution) reduces the average energy consumption per ton of POY (Pre-oriented Yarn) by 40% and that of FDY (Fully-drawn Yarn) by as much as 55% compared to the machines produced in the mid-1990s. Our latest solutions are therefore highly energy efficient,” explained Mr Wissenberg.

“Our new technologies also increase productivity, as illustrated by another example: The efficiency of the latest model of the WINGS FDY 32-end yarn winder is more than 2.6 times that of the previous ACW FDY 12-end model. This was enabled by the larger number of yarn ends and the optimization of the production process. The savings potential of the POY winder is similar.”

“Industrial production will always affect the environment. By consistently minimising these effects, we are emphasising our responsibility for creating a worthwhile future. Our German sites in Remscheid, Neumünster and Chemnitz are all DIN ISO 50000-1 certified. This means we have enforced a strict energy management programme which has to achieve a 1.5% reduction in energy consumption year on year,” commented Mr Wissenberg.

“We help to reduce negative influences to a minimum by applying the latest scientific and technical findings. Our products achieve this by, among other things, making the best possible use of all the raw materials used in our production process, a clear reduction in emissions, optimal energy balances and in some places, a significant reduction in required space.”

“We've already successfully launched two innovations onto the market back at the beginning of this year. One was the new, high-efficiency RoTac³ rotating tangle unit in which the compressed air supply is reduced by up to 50%, depending on the type of yarn; the other was the new VarioFil rPET with WINGS POY developed in close cooperation between Oerlikon Barmag and our affiliated company BBE Engineering.”

“We are also working on new technology and service solutions in all of our product ranges to offer our customers solutions which will continue to allow them to be competitive,” added Mr Wissenberg.

Business intelligence for the fibre, textiles and apparel industries: technologies, innovations, markets, investments, trade policy, sourcing, strategy...

Find out more