Rieter completes real estate sale in Ingolstadt

Results of intensive R&D to be showcased at ITMA Asia + CITME 2021.

26th April 2021

Innovation in Textiles

|

Winterthur, Switzerland

Since the onset of the Covid-19 pandemic, Rieter has doubled down on its R&D efforts to accelerate the development of its suite of intelligent and automated machines and systems to enable customers to manufacture yarns more profitably, efficiently and sustainably.

The company’s latest developments will be showcased at the ITMA Asia + CITME 2021 textile machinery exhibition in Shanghai, China, from June 12 to 16.

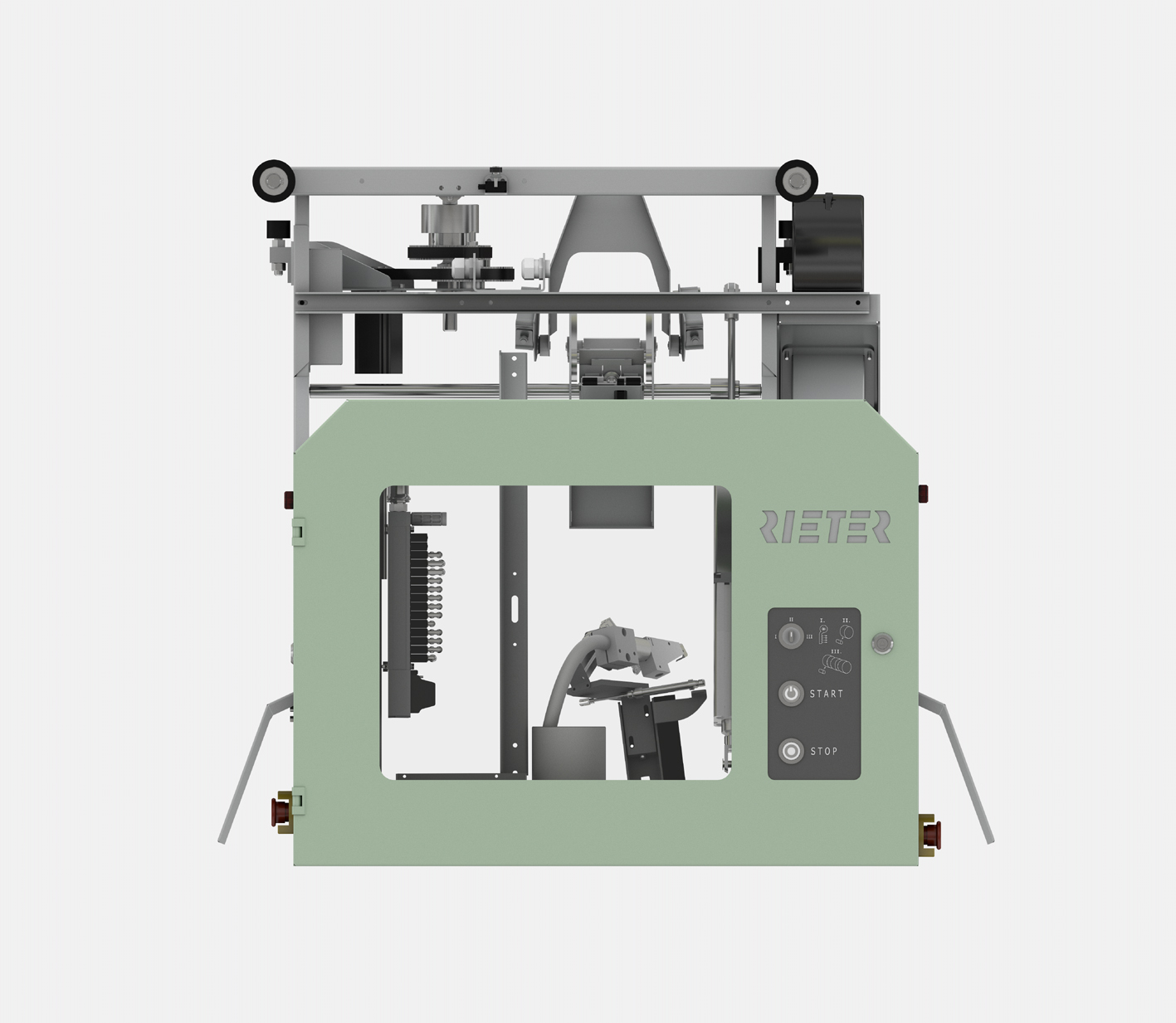

Rieter’s proven G 38 ring spinning machine, with up to 1,824 spindles, is now equipped with a fully electronic drafting system and the industry’s first fully automated piecing robot, ROBOspin. This powerful combination makes it easy to produce standard, special and compact yarns with the best-in-class compacting devices. The latest COMPACTapron incorporates 3D technology to guide the fibres smartly through the compacting zone.

Novibra’s HPS 22 spindle, which is available for ring and compact spinning, offers the best price performance across all applications, with spindle speeds reaching up to 22,000 rpm to meet a pressing need on the Chinese market.

The Essential monitor, one of the modules of Rieter’s all-in-one digital monitoring system, also has new features that provide smarter insights into a mill’s operations.

ROBOdoff

Manual doffing is cumbersome, time consuming and costly, and the ROBOdoff automates it, changing and replacing full packages with an empty tube that is prepared along each side of the machine so that the spinning process can continue seamlessly. It is available on the R 37 rotor spinning machine and as an option on R 35 and R 36 models.

The new 31-XT-BD rotor can meanwhile boost rotor yarn production by up to 6% for both knitted and woven applications. It is even possible to use lower quality raw materials while achieving constant production output.

The NEO-YW from SSM offers benefits for the dye package winding and rewinding of filament yarns and features a new online back pressure system for low and high package densities. Together with the firmly established fastflex thread laying system and digitens tension control technology, it guarantees the best dyeing results and unwinding properties.

The latest innovations from Graf include the P-1940S card cylinder wire and the resist-O-top C-60 flexible card flat. The cylinder wire delivers consistent sliver quality irrespective of the trash content of the incoming cotton fibres and extends lifetime by more than 10% thanks to a robust design and an increased blade width. In addition, the flexible flat resist-O-top C-60 reduces imperfections by up to 15% for fine count yarn spinners.

Rieter’s family of components, which spans Bräcker, Graf, Novibra, and Suessen, helps extend service life while enhancing quality and consistency.

Business intelligence for the fibre, textiles and apparel industries: technologies, innovations, markets, investments, trade policy, sourcing, strategy...

Find out more