Robotic assistance for Ugurlular Tekstil

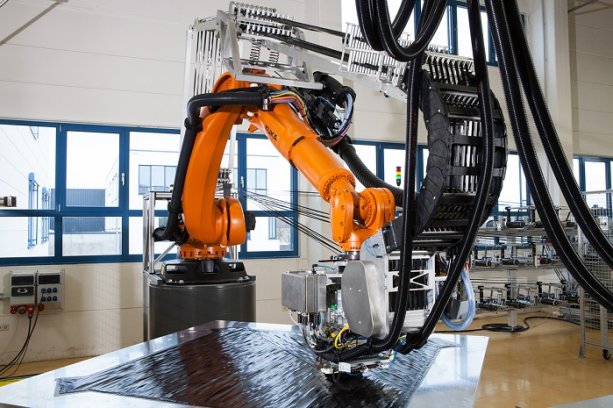

The patented automated fibre placement process of Compositence enables the cost-effective production of high performance, structural carbon composite parts for various markets.

23rd November 2016

Innovation in Textiles

|

Leonberg

Engineered for use with rovings, prepreg and thermoplastic tape, it results in savings in time, labour and materials over techniques relying on the manual lay-up of preforms.

In the Compositence process the robot applies carbon fibre, prepreg or unidirectional tapes directly to a lay-up surface.

The process is ideal for high production volumes. Compositence reports that it is typically more cost-effective than others starting from production volumes of several hundred parts. A plant that operates with 16 rovings with 3300 tex can lay-up an area of 1 m² with two orientations with a lay-up rate of 30 kg/hour. For a simple preform weighing 1 kg this results in a cycle time of 2 minutes. As a general rule, the larger the part and the lower the complexity, the higher the lay-up rate.

Business intelligence for the fibre, textiles and apparel industries: technologies, innovations, markets, investments, trade policy, sourcing, strategy...

Find out more