Shima’s cutting solutions on show in China

Demonstrating the latest in WHOLEGARMENT knitting technology will be the compact SWG061N2 WHOLEGARMENT knitting machine.

6th March 2017

Innovation in Textiles

|

Wakayama

Shima Seiki, a leading computerised knitting machine manufacturer, of Wakayama, will participate in the CeBIT 2017 international exhibition for digital business in Hannover, Germany, this month.

Shima Seiki will show as part of the Japan Pavilion hosted by Japan External Trade Organisation (JETRO). Known as a global leader in digitalisation, Japan is featured at CeBIT 2017 as official Partner Country of the exhibit. Shima Seiki will be part of the Japan Pavilion’s Infrastructure/Factory display.

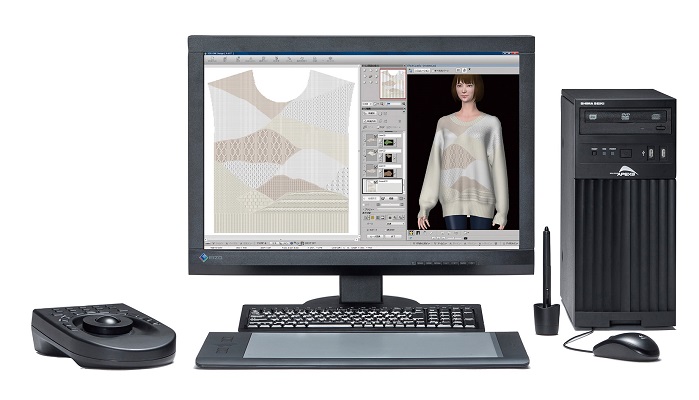

As the leading event on everything digital, and the world’s largest exhibition for B-to-B solutions in cutting-edge technologies, CeBIT offers the opportunity for Shima Seiki to demonstrate its combination of seam-free WHOLEGARMENT knitting technology and its SDS-ONE APEX3 3D design system for supporting recent consumer trends, such as increased online shopping activity, that have changed supply chain requirements, with growing demand for mass customisation and short turnaround.

Demonstrating the latest in WHOLEGARMENT knitting technology will be the compact SWG061N2 WHOLEGARMENT knitting machine that is designed to offer great flexibility with the capability to produce a variety of items such as gloves, socks, leggings, hats and mufflers, as well as childrenswear and technical textiles.

Its versatility makes the SWG-N2 series ideal for a range of applications from production in large-scale knitting factories to sampling in design studios as well as R&D and educational facilities, the company reports.

WHOLEGARMENT knitting forms a synergy with the SDS-ONE APEX3 3D design system that has been developed to provide game-changing flexibility in the knit supply chain. Ultra-realistic simulation capability on APEX3 allows Virtual Sampling to minimise the impact that the sample-making process has on current manufacturing in terms of time and cost, the manufacturer explains.

“With this new manufacturing model, the production cycle can be shortened to such an extent that on-demand production is possible without being limited to seasonal cycles, effectively meeting head-on the growing demand for mass customisation,” says the company.

In addition, virtual samples can be used effectively for on- and off-line retailing in gauging demand prior to production.

Exhibition: CeBIT 2017

Date: Monday, 20 ~ Friday, 24 March 2017

Hours: 9:00AM ~ 6:00PM

Venue: Hannover Exhibition Grounds

Messegelände 30521 Hannover, Germany

Tel: +49 511 89-0

Organiser: Deutsche Messe AG

Tel: +49 511 89-0

Booth No.: Japan Pavilion

Hall 12, Stand D04, (7)

Shima Seiki MFG., LTD.

Tel: +81 73-474-8210

Shima Seiki Italia S.p.A.,

Tel: +39 02 216621

Email: [email protected]

Business intelligence for the fibre, textiles and apparel industries: technologies, innovations, markets, investments, trade policy, sourcing, strategy...

Find out more