Stäubli displays state-of-the-art automation solutions

Stäubli will be promoting its technology at the Exintex trade fair, which opens its doors in Puebla, Mexico, this October.

16th July 2018

Innovation in Textiles

|

Pfäffikon

Stäubli will be promoting its technology at the Exintex trade fair, which opens its doors in Puebla, Mexico, this October. “This major business platform for the Latin American textiles industry is taking place within a challenging economic environment,” the company says. “For weaving and knitting mills to remain competitive, they must find ways to boost productivity and efficiency.”

“Visitors to the Stäubli booth will have an excellent opportunity to find out how Stäubli’s solutions for workflow automation, automated weaving preparation, shedding for frame and Jacquard weaving, and sock knitting can help them optimize their mill operations and reinforce their market position.”

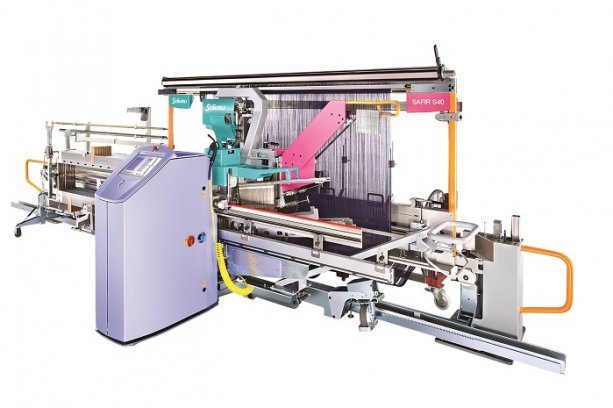

With the Safir S40 automatic drawing-in installation, Stäubli offers time savings in the weaving preparation process for cotton fabrics. Featuring AWC (ActiveWarpControl) technology, this machine is designed to assure one-stroke drawing in into drop wires, healds, and reed, resulting in aligned yarns with no crossed or double ends. The end product of this warp preparation is a prepared weaving harness that leads to high-quality fabrics and higher weaving machine output.

The range of Stäubli cam motions and dobbies includes machines for any type of weft insertion system for any application. The latest generation of the S3000 and S3200 series of rotary dobbies incorporates a new locking system, which is the heart of every dobby. This feature is said to provide enhanced security for heald frame selection, allowing higher running speeds, superior reliability, and less noise and vibration.

When it comes to Jacquard weaving, mills can choose from Stäubli’s range of Jacquard machines. The SX model is robust, wear-resistant, and designed for many years of daily use with a minimum of maintenance. Available in two formats (1,408 or 2,688 hooks), the machine supports excellent results in the form of e.g. terry cloth, apparel fabrics, or seat cover fabrics.

For large-format patterned fabrics with heavy weaving loads, Stäubli offers the LX series, including the LXL Jacquard machine, designed for extra-heavy load capacity. “From terry cloth to technical textiles, Stäubli Jacquard machines master every challenge and allow the mill to profit from quality results while reducing production time thanks to very high running speeds,” the company says.

The company also offers its recently launched D4S device, an automation solution that has been developed to shorten the production process for socks. The D4S can be mounted directly on the circular sock knitting machine; it closes the sock immediately after knitting.

Business intelligence for the fibre, textiles and apparel industries: technologies, innovations, markets, investments, trade policy, sourcing, strategy...

Find out more