Hohenstein releases quality labels for workwear

Different test methods differ in the test procedure, test set-up and conditions, making it difficult to compare the test results that cannot always be reproduced.

29th September 2014

Innovation in Textiles

|

Boennigheim

Breathability has been put under test at the Hohenstein Institute to examine and compare different standardised testing methods for measuring the water vapour resistance of textile products.

Silke Off, Head of the Clothing Physiology Laboratory at the Hohenstein Institute, used the following case study to explain the confusion that some customers may be faced with when trying to establish some of the qualities of the product.

Mrs Müller has submitted a complaint about the breathability of her recently purchased outdoor jacket, in which she sweats and feels uncomfortable.

According to the label, the vapour permeability of the jacket is 3000g/m2 in 24 hours. Mrs Off explained: “Vapour permeability of 3000g/m2/24h is the equivalent of a Ret value (resistance to evaporative heat loss) of about 40 m²Pa/W. That indicates poor breathability.”

“A good value would be over 10,000 g/m²/24h, and a very good one about 27,000 g/m²/24h. Textiles having that kind of value make the product very breathable.”

Mr Bohrer, from Quality Management, was given the task to find out where the fault lies and how the product could be improved, or what advice should be given to Mrs Müller. In order to do this, he needs to test the water vapour resistance of the product so he can determine the breathability.

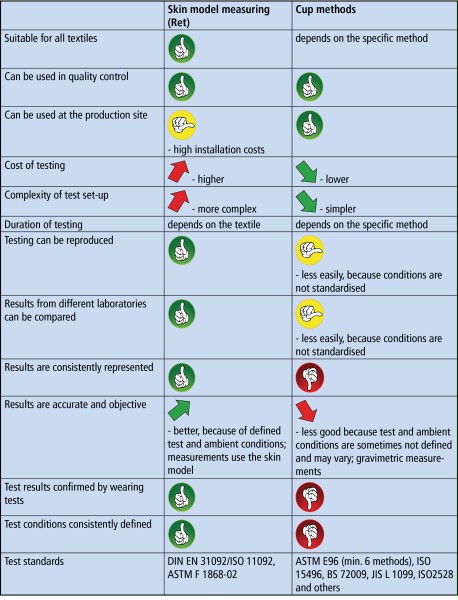

Various standardised test methods have become established that would enable Mr Bohrer to do so, some of them gravimetric methods, i.e. cup methods, and others called sweating guarded-hotplate methods, based on measurements taken using a skin model.

The problem lies in the differences between the methods. They differ in the test procedure, test set-up and conditions, in which the test is carried out and in the units used to express the results. It is therefore difficult to compare the test results and they cannot always be reproduced.

“For production control, the cup methods can offer a relatively quick and above all cheap solution. However, how the breathability of a textile is perceived when it is worn can only be measured using the skin model,” commented Mrs Off.

So, If Mr Bohrer tests the Ret value using the skin model, then he can not only evaluate the breathability but also the wearing experience that Mrs Müller complained about.

On the basis of the results of the Ret value test, which in theory he should be able to obtain from the supplier, he can both identify any potential for improvement and also give his customer the advice she needs. For Mrs Müller it means that she should not rely on advertising claims.

Numerous standards define the various cup methods for determining water vapour resistance. These include the desiccant method (ASTM E 96 A, C, E), the water method (ASTM E 96 B, D) and the inverted cup method (ASTM E 96 BW).

All the cup methods are based on determining the amount of water vapour that passes through a textile by gravimetric analysis, i.e. by weight. From the measurements, the permeability to water vapour, i.e. the breathability of a textile can be calculated.

The sweating guarded-hotplate method calculates the Ret value, the water vapour resistance of a textile. This is measured using a skin model (sweating guardedhotplate).

The main component of the skin model is a porous sintered metal plate, heated to 35 °C. The textile being tested is placed on the hotplate and water vapour is passed through the pores of the hotplate. This simulates the evaporated sweat with which a textile comes into contact.

The test is carried out in standardised conditions in a climate-controlled cabinet in which defined ambient test conditions have been set.

Business intelligence for the fibre, textiles and apparel industries: technologies, innovations, markets, investments, trade policy, sourcing, strategy...

Find out more