Rieter acquires Schlafhorst

Saurer has delivered its Autoconer 6 in a brand-new version geared to E³ to the first customers at the beginning of the year.

10th March 2016

Innovation in Textiles

|

Übach-Palenberg

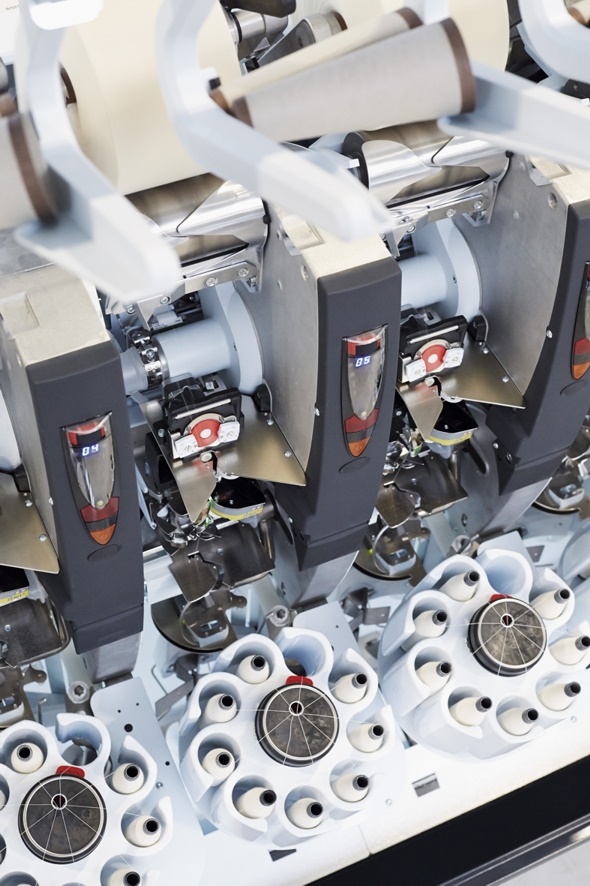

Saurer, a leading textile industry group, has delivered its innovative Autoconer 6 automatic package winder to the first customers at the beginning of the year.

The German textile machinery manufacturer has presented the Autoconer 6 in a brand-new version geared to E³ to the general public at ITMA 2015 that took place in Milan last November. E³ is the company’s unique concept, representing triple added value in the energy, economics and ergonomics categories.

A string of unique innovations has enabled Schlafhorst to reduce the energy consumption of the Autoconer 6 by up to 20%, compared with its predecessor, the company reports.

A key contributory element here is the new Eco-Drum-Drive System in the self-adjusting winding unit. Thanks to the latest drive and bearing technology, the Eco-Drum-Drive System is said to save a considerable amount of energy.

The new Autoconer 6 is also said to achieve a double-digit increase in productivity. Whilst the basic model is 6% more productive than its predecessor, the new model has demonstrated 12% more productivity, according to the manufacturer.

LaunchControl boasts the latest process intelligence for a slip-free, self-optimised start-up. Higher acceleration and faster deceleration of the winding system are possible using the innovative Eco-Drum-Drive System.

Intelligent sensor technology and smart process control turn the Autoconer 6 into an automatic package winder. The functional design and optimised process sequences are said to minimise downtimes and malfunctions, so that manual intervention by the staff is practically unnecessary.

Smart electronics and mechanical innovations complement one another in this design. Autocalibration of the splicer feeders and suction tubes relieves the burden on the operators substantially. The X-Change doffer assumes additional functions too: with Tube Check it detects tubes that are not round via laser and removes them automatically.

Once again the Autoconer 6 sets the benchmark in splicing with the new SmartSplicer model family. Its completely revised splicer geometry is designed to ensure the best splice quality in every application with the simplest handling. The splicing parameters can be entered conveniently at the Informator.

The SmartSplicer will splice all common standard, compact and blended yarns. For extreme strength and an even better appearance, especially for denim, linen and OE yarns, the SmartSplicer Injection is used. The SmartSplicer Thermo is recommended for wool and wool-blend yarns, while for elastic core yarns Schlafhorst offers the SmartSplicer Elasto.

Schlafhorst offers its customers various automation solutions. With VarioReserve, Intelligent Bobbin Sharing, High Speed Feeding and various automation units, Schlafhorst aims to ensure profit-enhancing process reliability and minimal reliance on personnel in every spinning mill.

A new standard has also been created for the Autoconer 6, type RM machine with its unique new circular magazine and the 9+1 bobbin feed concept.

The Autoconer package is said to offer a great interaction between the new standard yarn tension control system TensionControl, the unwinding accelerator, the new Eco-Drum-Drive System, effective electronic anti-patterning and optionally the new gate tensioner or the disc tensioner, for a package density of better uniformity.

The Autoconer 6 introduces broad range of package formats: cylindrical and tapered up to 5°57’, with traverse widths from 3" to 6". Packages with a diameter of up to 326 mm can be produced on the Autoconer.

Business intelligence for the fibre, textiles and apparel industries: technologies, innovations, markets, investments, trade policy, sourcing, strategy...

Find out more