Textechno announces partnership with AZL

The new technology has been developed to measure the most important properties of rovings all at once.

28th February 2017

Innovation in Textiles

|

Mönchengladbach/Aachen

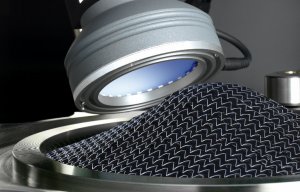

Textechno, a leading designer and manufacturer of precision test equipment for fibres, yarns and rovings in textile and composite applications, will be launching its latest equipment ROVINGTEST at JEC World, in Paris, next month. The new technology has been developed to measure the most important properties of rovings all at once.

Textechno, a leading designer and manufacturer of precision test equipment for fibres, yarns and rovings in textile and composite applications, will be launching its latest equipment ROVINGTEST at JEC World, in Paris, next month. The new technology has been developed to measure the most important properties of rovings all at once.

“The ROVINGTEST can be used to characterise all yarns and rovings made from reinforcement fibres like carbon and glass. ROVINGTEST is worldwide the first ever commercially available multifunctional testing system to measure performance and properties of rovings either all in one or separately,” explained Dr Ulrich Mörschel, CEO of Textechno.

According to the manufacturer, one important group of parameters assessed by ROVINGTEST are the friction properties of rovings to metal or ceramics and the existence or generation of broken filaments, for example, due to the contact with surfaces. Moreover, the friction from roving to roving can be measured, which is an important parameter, for instance, as input for precise simulations of draping and forming processes.

“Spreading behaviour and homogeneity of filament orientation can also be measured by our new testing system, the latter on carbon fibres,” said Dr Mörschel. “These are especially important in the production of organosheets and tapes. Costly and lengthy trial productions are minimized, reproducible measurement results become comparable and easily accessible for the user. ROVINGTEST hence helps to increase both, processability and the performance of the final composite.”

Automated processing

Automated processing“The determination of characteristic values of rovings is very important for the automated processing of the final composite parts,” commented Dr Michael Effing, CEO of AMAC GmbH and senior advisor for fibre-reinforced plastics to Textechno.

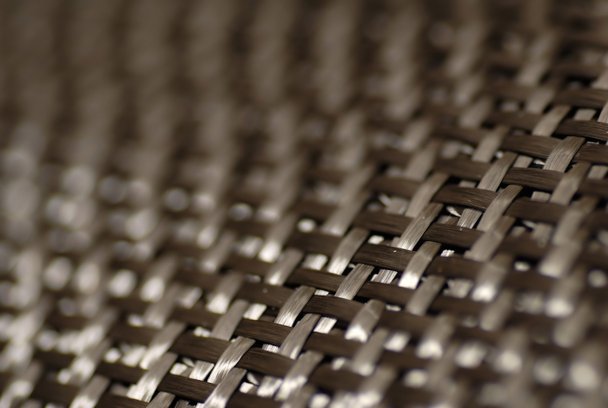

“Rovings are used in high volume applications and processes like filament winding of pipes, pultrusion of profiles and multiaxial warp knitting for wind energy rotor blades. Thermoplastic composite tapes are gaining importance and the spreading behaviour of rovings is a key to success.”

Textechno is a leading designer and manufacturer of precision test equipment and systems for textiles and man-made fibres, headquartered in Mönchengladbach, Germany. Established for more than 60 years, Textechno is, together with its subsidiary Lenzing Instruments in Austria, a market and technology leader in the field of man-made fibre and filament testing.

Textechno is member of AVK and received the JEC innovation award for FIMATEST, a system for the quality assessment of the adhesion strength between fibre and matrix in reinforced plastics.

Business intelligence for the fibre, textiles and apparel industries: technologies, innovations, markets, investments, trade policy, sourcing, strategy...

Find out more