Autefa to offer future-proof solutions at Techtextil

At ITM Autefa Solutions will show innovative solutions for the processing and recycling of carbon-, glass-, aramid- and natural fibres.

19th March 2018

Innovation in Textiles

|

Friedberg

Autefa Solutions, a full line supplier for carded- crosslapped needlepunch lines and thermobonding lines, will discuss the economic and technical advantages of its technological solutions at the upcoming ITM trade fair in Istanbul, next month.

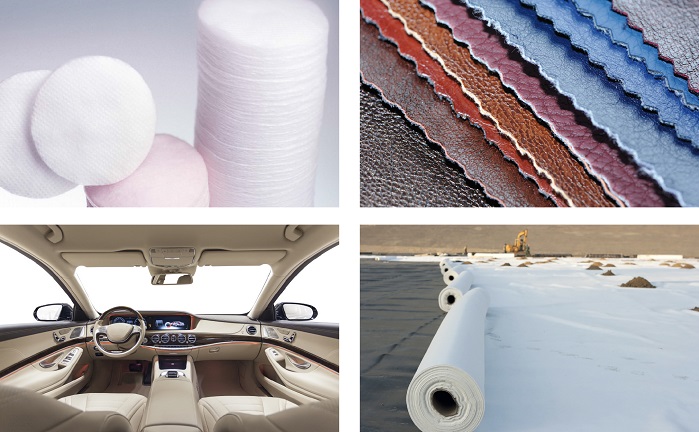

The Turkish nonwovens market covers almost all application fields. Typical applications of needle-punched nonwovens are the production of artificial leather, automotive felts, carpets and carpet backings, insulation materials for thermal and noise insulation, geotextiles, industrial wipes and technical felts.

“We see an increasing demand in reliable and cost-efficient production lines for the highly-competitive automotive market. Our customers need high-speed lines and an improved quality,” commented Giacomo Meucci, Regional Sales Director, Autefa Solutions.

At ITM Autefa Solutions will show innovative solutions for the processing and recycling of carbon-, glass-, aramid- and natural fibres. Since 2010, the company is concerned with the re-utilisation of recycled carbon fibres to carbon fibre nonwovens and has already successfully placed production lines in the market.

The Web Master Futura card is developed and designed for high production speeds with a special focus to improve the cost factor of maintenance. The different modules of the card, means feeding group, main cylinder, transfer group and doffers, are each placed on a separate carriage. The carriages are connected to each other and form a “train”, which allows easy and full access for cleaning and maintenance.

The crosslapper Topliner in combination with Web Profile Control WebMax is the key to the web quality, the company reports. “It optimises the CV-value, which leads to significant reduction of material costs. The two drafting zones of the WebMax ensure a slight pre-draft and a precise draft of the web in the second drafting zone. This is of special importance to guarantee constant quality at high production output t with all raw material types.”

Autefa Solutions has developed and patented the V-Jet injector. It is installed in several productions and led to significantly higher tensile strength at same entangling water pressure than a standard injector, according to the manufacturer. The possible reduction of water pressure is in the range of 20%. In addition, the water consumption is reduced by 10% when using the same nozzle diameter and pitch. Depending on the application, this new technology leads to an energy saving of up to 30%. The new Square Drum Dryer SQ-V combines the advantages of a horizontal dryer with the lower space requirement of a conventional drum dryer.

The nozzle system in the Autefa Solutions Square Drum Dryer SQ-V is designed to uniformly distribute the airflow in terms of speed and temperature throughout the whole working width, providing best spunlace web and surface quality results.

Autefa Solutions delivers machines for opening, blending and carding, as well as ovens and dryers out of one hand. Autefa Solutions high-speed oven HiPerTherm HS offers accuracy airflow system with high production speeds up to 250 m/min. The HiPerTherm HS is a single belt oven for thermobonding and drying. The double nozzle system allows the creation of extremely uniform product treatment.

The key strengths of the Autefa Solutions belt dryers are high uniform airflow, the adjustable temperature distribution and the ability to maintain loft. The machine has been especially designed for the manufacturing of top sheets and ADL what demands utmost accuracy. The nozzle design is said to prevent dust accumulations and ensure the capture of dust in the automatic filter systems.

Business intelligence for the fibre, textiles and apparel industries: technologies, innovations, markets, investments, trade policy, sourcing, strategy...

Find out more