Tailor-made for electric vehicles

Hybrid-Acoustics PET from Autoneum stands for lighter, quieter and more environmentally friendly vehicles.

5th November 2019

Innovation in Textiles

|

Winterthur

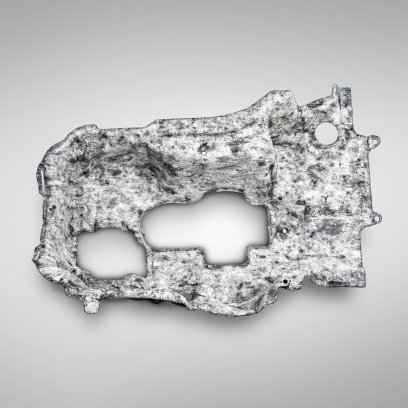

Hybrid-Acoustics PET. © Autoneum.

Hybrid-Acoustics PET from Autoneum stands for lighter, quieter and more environmentally friendly vehicles. The product innovation for vehicle engine bays is not only characterized by lightweight construction and noise protection optimized for electric vehicles, it also convinces through sustainability, the company reports. Components made of Hybrid-Acoustics PET consist entirely of PET, which is largely obtained from recycled fibres, meeting customer demand for environmentally friendly mobility solutions.

With Hybrid-Acoustics PET, Autoneum has adapted its textile interior technology Hybrid-Acoustics for use in the engine compartment. The patented innovation is based on a unique fibre material that acts as an insulator and absorber at the same time. Hybrid-Acoustics PET is also used to encapsulate electric motors, thereby reducing noise directly at the source and particularly attenuating high-frequency sounds of the electric drive unit. This key technology accordingly ensures optimum noise protection in the passenger cabin and greater driving comfort, the company adds.

According to Autoneum, components made of Hybrid-Acoustics PET convince with their low weight. Compared to conventional insulators, they are said to be up to 40% lighter, contributing to a greater driving range. They are also flameproof and find application as powertrain-mounted insulators for combustion engines thanks to their temperature resistance of up to 180°C.

The parts, which consist to a large extent of recycled PET fibres, are produced waste-free and are completely recyclable – an outstanding life cycle assessment compared to equivalent components in the engine bay, Autoneum explains.

“Hybrid-Acoustics PET therefore exemplifies Autoneum's commitment as part of its Advance Sustainability Strategy 2025 to continuously improve the environmental performance of its product portfolio and thus contribute to a resource-efficient mobility”

Starting in spring 2020, e-motor encapsulations made of Hybrid-Acoustics PET are being produced for various new electric models of a Swedish car manufacturer at the company’s Taicang plant in China (Jiangsu province). In addition, Autoneum will supply engine mounted parts to various French and Japanese vehicle models with combustion engines from its site in Ons-en-Bray, France.

Business intelligence for the fibre, textiles and apparel industries: technologies, innovations, markets, investments, trade policy, sourcing, strategy...

Find out more